Versatile and reliable in all conditions – the GX 360 Plus transport wagon!

The GX wagon has a load volume of 44 m³ and is designed to meet the changing needs of modern farming. Thanks to its flexible design and robust construction, the GX can transport a wide variety of materials and crops, while its user-friendly features ensure both loading and unloading can be done with maximum precision.

The GX wagon has a load volume of 44 m³ and is designed to meet the changing needs of modern farming. Thanks to its flexible design and robust construction, the GX can transport a wide variety of materials and crops, while its user-friendly features ensure both loading and unloading can be done with maximum precision.

Loading flexibility

The KRONE GX is designed to meet the varying needs of farming. Whether you're transporting root vegetables like potatoes and beets, grains like wheat and corn, or heavier materials such as wood chips and feed bags, the GX can handle any type of load. Its robust construction makes it tough enough for heavy materials while gently managing sensitive crops that are easily damaged. This flexibility makes the GX an indispensable tool for farmers needing a reliable wagon year-round for various tasks and materials.

High load capacity and great visibility

With an impressive load capacity, the GX can handle large amounts of material in one trip, streamlining workflow and saving time. The wide opening enables fast and efficient loading, while the adjustable side walls add extra flexibility for handling different types of cargo. The large inspection windows on the wagon give the operator a clear view of the loading area, minimizing the risk of overfilling and spillage. This oversight ensures smooth operations and that crops are loaded in a controlled manner.

Moving floor and wall for efficient unloading

The GX is equipped with a moving floor and wall system, allowing for quick and gentle unloading. The floor and front wall work in harmony to evenly move the material backward, ensuring efficient unloading without damaging sensitive crops like potatoes or silage. This technology also enables the fast handling of large volumes, which is particularly valuable during busy harvest periods. The smooth and controlled movement ensures that the material maintains its structure and quality throughout the entire process.

GX PLUS – Simplicity and functionality

The PLUS variant focuses on simplicity and safety, ideal for those who need a robust wagon without advanced technology. This model operates without ISOBUS and is controlled via the Pre-Select system, making it both easy to use and reliable in all conditions.

A versatile transport wagon

The KRONE GX is designed to handle various materials all year round. In winter, the wagon is ideal for transporting snow and straw, while during the harvest season, it easily manages crops like beets, corn, and grain. Sensitive crops, such as potatoes and root vegetables, are gently handled thanks to the moving floor, which reduces drop height and protects the crops from damage. No matter what material you’re working with, the GX provides a reliable solution for safe and efficient transport.

Robust and durable drive system

The KRONE GX is equipped with heavy-duty flatlink chains under the floor, designed to withstand the toughest working conditions. These durable chains are made from materials that ensure long-lasting performance, even with intensive use. Connected to the floor belt, the chains work seamlessly to guarantee smooth and efficient material movement.

Powerful unloading system

The GX wagon features a powerful unloading system driven by two hydraulic motors and robust gearboxes. This system enables smooth and controlled unloading, with adjustable speeds for different types of material. Whether handling large volumes or sensitive crops, the system ensures fast and efficient unloading, optimizing workflow.

Gentle and even unloading

The front wall and floor belt work in perfect harmony to gently move the material backward, minimizing the risk of damaging crops during the unloading process. This coordinated system ensures an even flow of material, which is especially important when handling crops that require extra care to maintain their quality.

Smooth loading with wheel loaders

Thanks to its telescopic sides, loading compost becomes simple and efficient. The adjustable sides can be lowered to facilitate loading with wheel loaders or telescopic loaders, allowing quick filling with minimal spillage. This feature ensures that large volumes can be loaded without material loss, increasing both precision and efficiency in operations.

Flexible and adjustable drawbar

The hydraulic drawbar can be easily adjusted to modify ground clearance, allowing the wagon to adapt to different terrain and tasks. This is particularly useful when working on uneven or hilly ground, where the adjustable drawbar ensures smooth maneuverability and stability. Additionally, the front of the wagon can be lowered as needed, making it quicker and easier to load, especially when following a forage harvester opening a field.

Smooth and comfortable ride

The hydraulic suspension absorbs shocks from uneven terrain, and combined with the large tires, which can be up to 30.5 inches, it ensures an incredibly smooth ride. This creates a comfortable working environment for the operator and reduces strain on both the machine and tractor. The combination of suspension and large tires contributes to improved stability and enhanced comfort, allowing work to be completed faster and more efficiently, with less wear on equipment.

Easy filling with tapered sidewalls

The tapered sidewalls create a wider opening at the top, making it easier to load the wagon with different types of material without worrying about anything getting stuck or spilling over the sides. This design also reduces the risk of material sticking to the walls during unloading, ensuring the entire load is emptied evenly and quickly. Combined with the wagon's lightweight yet robust construction, the tapered sidewalls not only optimize load capacity but also streamline workflow, saving time and energy in the field.

Adjustable sides for delicate crops

The GX wagon features adjustable sidewalls that can be lowered by up to 660 mm, reducing drop height and protecting sensitive crops like potatoes and beets from damage during loading. This function allows for gentle handling of crops while improving efficiency. The adjustable sides also make loading easier and more flexible, accommodating different types of machinery and specific operational needs.

Full visibility into the loading area

The large acrylic windows on the front wall provide the operator with a clear view of the entire loading area. These windows make it easy to monitor the loading process in real-time and ensure that filling is done correctly and evenly. Having full visibility allows the operator to quickly adjust the process if needed, minimizing the risk of overfilling or spillage. This not only improves workflow but also ensures crops are handled optimally, enhancing efficiency and safety during both loading and transport.

Lightweight but durable construction

The GRP (glass fiber-reinforced plastic) construction makes the wagon both lightweight and extremely robust. Despite its low weight, it offers impressive durability, allowing it to handle large loads without compromising performance. The lightweight design also reduces fuel consumption during transport and improves maneuverability, both on the road and in the field. At the same time, the durable materials ensure the wagon withstands wear and tough working conditions, providing long-lasting and reliable performance even under intensive use.

Flexible tailgate for fast loading

The flexible tailgate with two discharge rollers makes the loading process both fast and smooth. When the rollers are not needed for unloading, they can easily be folded away, freeing up the entire load area and enabling quicker and more flexible loading. This design minimizes the time spent switching between different tasks, whether you're loading or unloading. The practical mechanism also makes it easy to adapt the wagon to different types of loads, enhancing efficiency and ensuring a steady workflow without unnecessary interruptions.

Clever folding

The KRONE GX boasts a clever tailgate design. The discharge rollers can be attached to the sides or the tailgate in just seconds. No assistance is needed to refit the two bolts at the ends of the rollers—an ingenious solution that speeds up changeovers.

Even and gentle distribution

The discharge rollers are designed to ensure even and controlled distribution of material, whether it's silage, grain, or other crops. This consistent spreading makes it easy to compress and pack the material, which is crucial for maintaining quality and efficiently using storage space. By spreading crops in an even layer, the rollers create optimal conditions for compression, improving storage durability and ensuring the material is preserved in the best possible condition.

Stable and reliable chassis

The wagon features a heavy-duty chassis equipped with hydro-pneumatic suspension, providing both stability and comfort regardless of terrain conditions. This robust system allows the wagon to handle uneven ground and heavy loads while maintaining control and smooth driving.

Save tires and reduce wear

During empty transports, one of the axles can be lifted to reduce tire wear and save resources. This extends the lifespan of the tires and lowers operational costs, especially when driving on roads without a heavy load.

The braking system

The GX 440 and GX 520 are equipped with dual-line air brakes as standard. The hydraulic ALB valve automatically adjusts braking power according to the current load. Spring-accumulated brake cylinders ensure the wagon remains safely parked, regardless of terrain.

ISOBUS control Plus

The hydraulic functions of the GX 360 and 440 PLUS models are preselected as standard via PreSelect Digital on the ISOBUS terminal and are then controlled using the tractor's hydraulic valves. For added comfort, the function presets can also be programmed on the tractor's control lever. Alternatively, the Pre-Select DS 50 provides a separate control unit for preselecting the hydraulic functions.

Safety features

- LED working lights for safe operation both in the field and on the road.

- Excellent all-around visibility during nighttime work.

- Standard position lamps for high visibility at night.

- For added safety, the wagon can be equipped with reflective contour markings.

- A hydraulic underride guard is standard equipment.

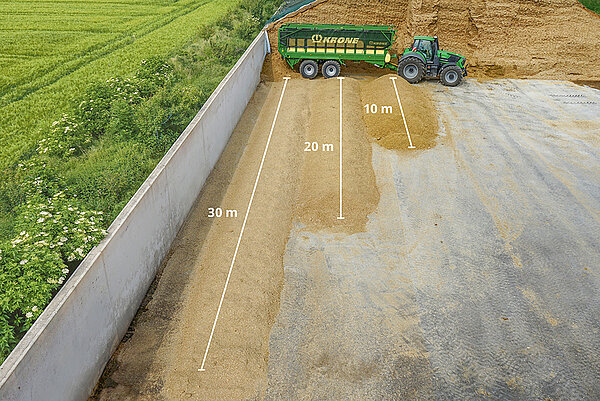

Flexible unloading with ExactUnload (optional)

With ExactUnload, you can set how quickly and evenly the crops should be emptied over a predefined distance, which is especially useful during silage operations. The even distribution of material reduces the need for manual adjustment, saving time during work. This function also ensures that the crops are spread consistently, contributing to optimal compaction in the silage pit and improving the quality of the silage.

Underride guard

A hydraulic underride guard increases safety when driving on public roads. It can be folded up to facilitate maneuvering when working with chasers and harvesters. Additionally, no crops collect on the guard when it is folded away. The guard automatically lowers into road position once the speed reaches 15 km/h.

SmartConnect

KRONE Smart-Connect is a telemetric system offered as an option for the GX model. With GPS and Wi-Fi functionality, it serves as an interface to your data management system. Telemetrics allow you to track the wagon and collect vital data, which is then sent directly to the office. This is the future of farming – smart, efficient, and connected.

Cameras (optional)

The GX models can be equipped with optional cameras, one providing images from inside the wagon and another serving as a reverse camera. The monitor features a switchable color display that makes harvesting easier and safer.

Remote control (optional)

With the optional radio remote control, you can operate the GX wagon remotely from the ground. You can open and close the tailgate or control the unloading unit for the floor and front wall at variable speeds. This allows you to maintain full control without needing assistance.

External lights (optional)

Up to eight additional sidelights are available as an option for the KRONE GX model, illuminating the axle and the area around the machine. This makes it safer and easier to maneuver and drive alongside the harvester at night, as well as enhancing safety during work at the silo.

Internal lights (optional)

As an option, LED lights can be installed inside the load space for optimized visibility. Indirect lighting makes it more comfortable to fill the machine from the harvester, especially when working in the dark. These lights can also be linked with the tractor's lighting for smooth and coordinated light control.

Crop covers (optional)

As an option, the wagon can be equipped with crop covers to protect the load during transport. These covers open and close hydraulically, making it easy to secure the load during fast road transport. With this option, you can be sure that no material is lost during transit.

Reading the current load (optional)

The load weight is clearly displayed using pressure gauges that indicate the pressure inside the hydraulic cylinders on the articulated drawbar and the wagon chassis. This feature provides a reliable and simple overview of the current load capacity, helping you work safely and efficiently.

Electronic weighing system (optional)

The optional electronic weighing system uses sensor pins on the drawbar and on the tandem or tridem axle to measure the load with hydraulic pressure compensation. The weight of the load is calculated based on the load on the drawbar and axle and is clearly displayed on a screen. Additionally, the weight is recorded for each task, providing a detailed overview of the work.

-

Type of wagon Multipurpose wagon

-

Tractor power 120 hkr

-

Tractor power 88 kw

-

PTO speed 1000 rpm

-

Width 2.96 m

-

Height 3.95 m

-

Length 8.75 m

-

Permissible axle loads (with tandem unit) 18 000 kg

-

Permissible axle loads (with tridem unit) 20 000 kg

-

Max drawbar load 4 ton

-

Hydraulic couplers, tractor 1x DA+ 1x SA + free return. (If option, 1x SA + 1x DA)

-

Volume loading area 36 m3

-

Discharge rollers Optional

-

Number of discharge rollers, std (option) 2

-

Tandem wheel axle as standard

-

Tridem

-

Tyresize standard 800/45 R 26.5 TL

-

Wheel size, options 800/45 R 26.5 Trac, 710/50 R 30.5, 800/45 R 30.5 Trac

-

Track width 2,05 m

-

System PreSelect and tractor-side control valves

-

ISOBUS compatible

-

Terminal Optional

-

Cross conveyor unloading

-

Load cover Optional

General

Dimensions

Frame

Loading area

Wheels

Attached implements

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.