Här kan du se våra färdiga paket och är du inloggad ser du rätt pris istället för listpris. Har du andra önskemål om maskinutrustning? Kontakta våra produktspecialister för skräddarsydda lösningar.

Since 1985, the Dutch company GKB has developed user-oriented and innovative machines that are adapted to all types of sports surfaces. The SPM300 sand spreader is an excellent example of this. With a container capacity of 3000 liters (ironed size) and robust design and composition, GKB's SPM300 gives you many efficient operating hours over a long period of time to come. In addition, the GKB SPM300's control box provides full control and an overview of the work while you remain in the tractor.

The sand spreader has several smart functions that facilitate the work; the excess water can evaporate, oxygen enters the material and less organic material can form in the top layer. This results is cleaner sand and grass in top condition.

The sand is transported back to a dosing valve by means of a robust conveyor belt that can be speed-adjusted steplessly from the control box (the dosing valve is also available as hydraulically steplessly operated). The double, steplessly speed-adjustable and hydraulically driven spreading discs are adjustable in several points, which means that you can create the perfect spreading image of your sand. SPM300's conveyor belt can also drive forward to the front metering valve and can with an extra conveyor belt (optional) that you can discharge sand in, for example, bunkers. SPM300 is delivered with four swivel balloon tires as standard, all to ensure a perfect weight distribution on your sports field or golf course . SPM can also be equipped at the factory with lights and brakes approved for road transport.

GKB Discharge belt and arm

GKB SP Belt and Spreading discs

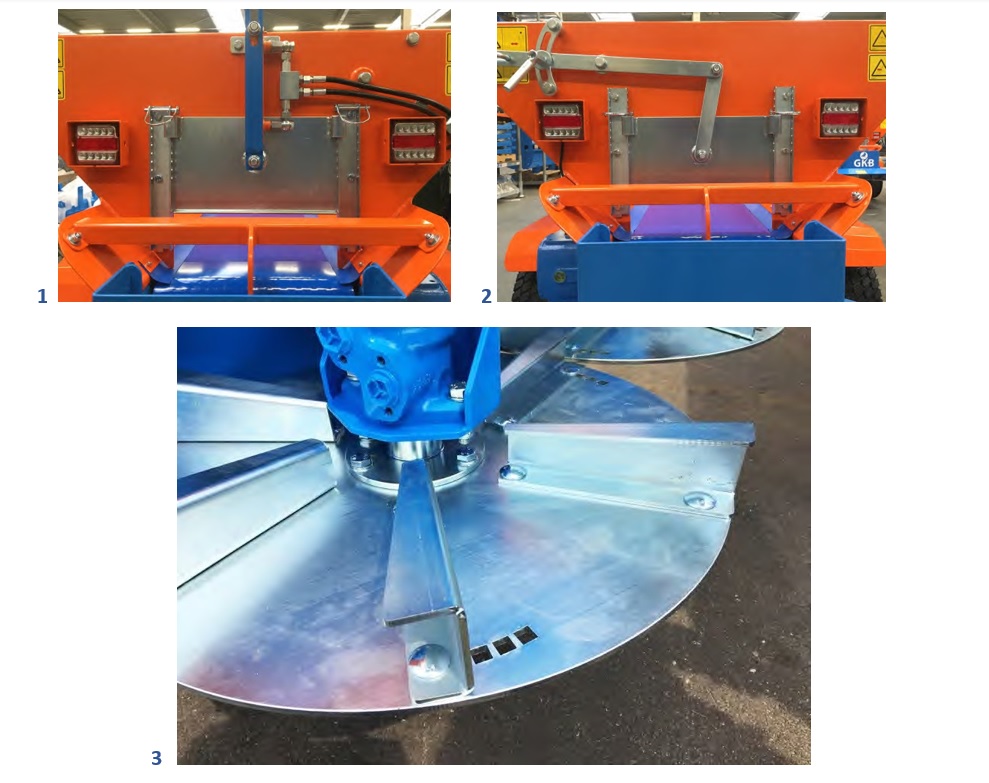

The shape and design of the sand bunker ensures an efficient

operation and ensures your clear view along the machine. The

sand is transported to a metering valve (1) by means of a conveyer

belt which, optionally, is also available as a hydraulically operated

metering valve (2). The double, hydraulically powered, spreading discs (3) are adjustable on multiple points, Via guider adjustment

There are six guiders mounted on each disc. These guiders spread the sand. The angle to the center determines sand distributi-on. A narrow spreading position gives a more even picture.

Consequently, the GKB Sandspreaders enables you to create perfect sand distribution.

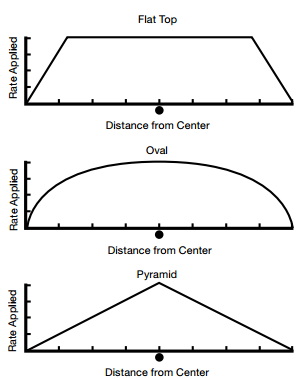

GKB Sand Spreading Patterns and Adjustments

To ensure the proper spreading pattern for your desired result, it is important to understand how to operate each component

and to learn what their individual effect is on the sand. The three most common spreading patterns are as follows:

OVAL SPREADING PATTERN: The oval or rounded image provides good results and is most commonly used. This pattern is optimal for spreading multiple strips.

PYRAMIDAL SPREADING PATTERN: If more sand is spread in the middle than at the edges, a pyramid-shape is created. If more than one row is scattered, an undulation occurs on the separation of the rows.

“V” OR "FLAT-TOP" SPREADING PATTERN When the sand is mainly spread at the edges, traces of sand are left on the field. On the separation of the tracks there will be a track of sand with almost no sand in the middle. In many cases, the cause lies in a dish distance that is too small in relation to the machine.

OVAL SPREADING PATTERN: The oval or rounded image provides good results and is most commonly used. This pattern is optimal for spreading multiple strips.

PYRAMIDAL SPREADING PATTERN: If more sand is spread in the middle than at the edges, a pyramid-shape is created. If more than one row is scattered, an undulation occurs on the separation of the rows.

“V” OR "FLAT-TOP" SPREADING PATTERN When the sand is mainly spread at the edges, traces of sand are left on the field. On the separation of the tracks there will be a track of sand with almost no sand in the middle. In many cases, the cause lies in a dish distance that is too small in relation to the machine.

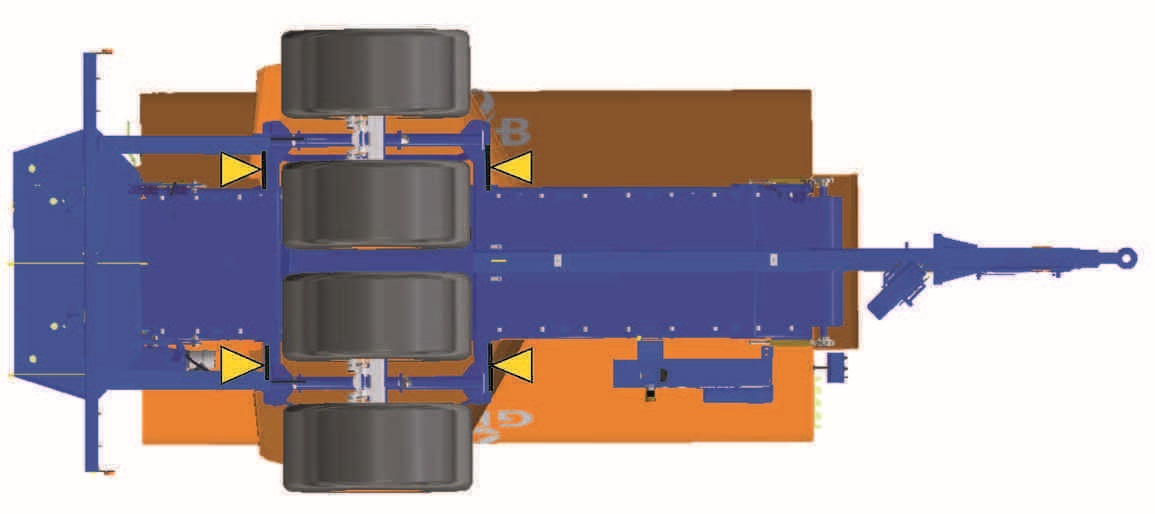

GKB 4 wheels on 2 oscillating axles

Under the frame there are two oscillating axles equipped with 2 wheels each.

Swinging wheelset and Sturdy wheelbase for perfect stability and weight dispersion

Why GKB

The machines that we develop are reliable, robust machines. We owe this fact to the fact that we are still working with the machines as well. We know what the man who does the work requires to operate in a good and efficient manner. Therefore, we are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you should purchased it.

GKB sustainability

At GKB Machines we feel strongly about sustainability, as a family-owned company we aim for a sustainable company with a positive future prospect. That we do not just stick to words is evident from the fact that we are producing our machines energy neutral.

Sustainability is also highly important during the development of the machines. We develop the machines from the experience we have established from our contractor division. Every GKB Machine must satisfy the high-quality requirements that we impose. A sustainable, reliable and robust machine is the foundation for your operation. Since our contractor division is used to receiving these type of machines, you might also expect this from us.

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

Sustainability is also highly important during the development of the machines. We develop the machines from the experience we have established from our contractor division. Every GKB Machine must satisfy the high-quality requirements that we impose. A sustainable, reliable and robust machine is the foundation for your operation. Since our contractor division is used to receiving these type of machines, you might also expect this from us.

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

-

Working spreading width 2-10 m

-

Capacity sandbunker 3000 l

-

Max axle load 8000 kg

-

Type of tire BKT 400/60-15.5

-

Unloading conveyor

-

Length unloading conveyor 4000 mm

-

Hydraulic requirement 40 lmin

-

Creeper gear required

-

Linkage Towing eye

-

Public road use

-

Hydraulic operated functions Yes, as option

Dressers

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.