Efficient grain analyses on the farm!

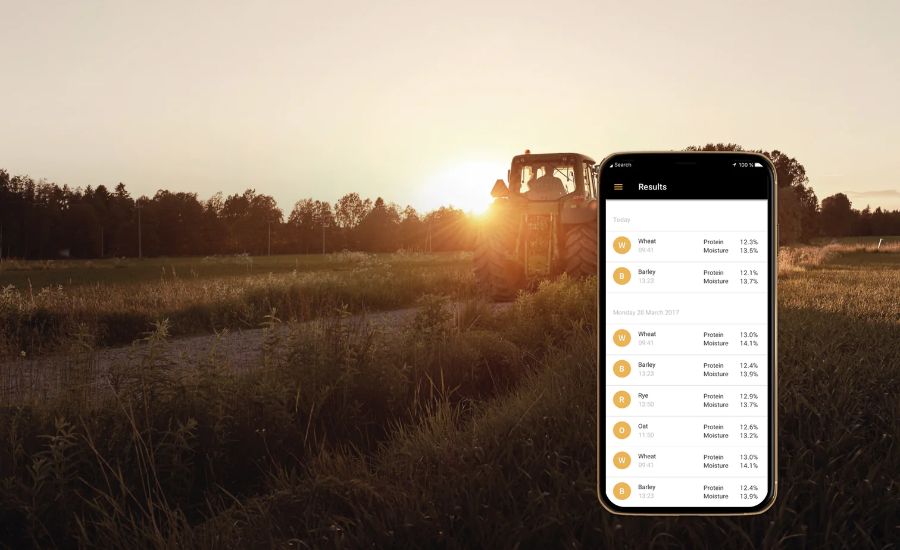

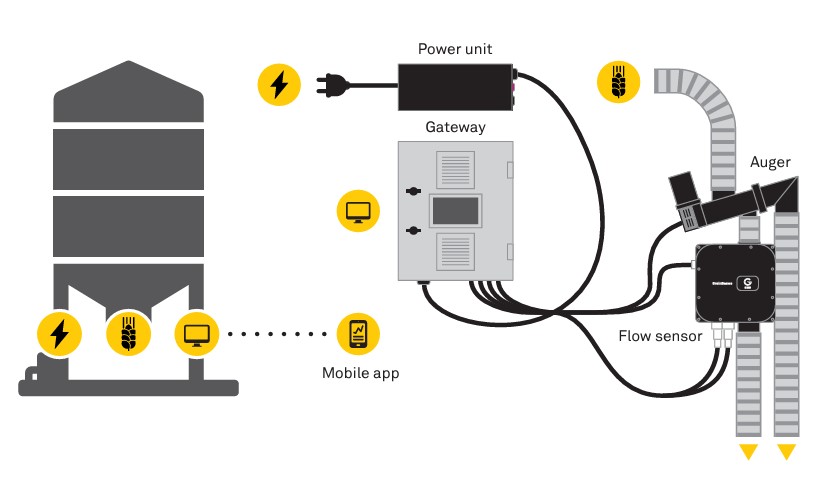

GrainSense Silo measures protein and moisture in grain and other crops in an actively flowing environment within a silo or dryer. Through an input and output system for grain, GrainSense Silo will continuously extract a sample of the grain from the connected system and perform a real-time and online quality analysis. Key values can be viewed on the device's display, and measurement data is sent to GrainSense Cloud, allowing the user to see the results in real-time and make quality-based decisions. From the continuous grain flow, a grain sample is extracted to GrainSense Silo's dosing screw, which in turn feeds a steady grain flow through the unit's sensors. This silo version comes with an installation insert tailored for mounting inside the silo and a camera that detects green and broken kernels by using state-of-the-art camera technology and artificial network computing.

GrainSense Silo measures protein and moisture in grain and other crops in an actively flowing environment within a silo or dryer. Through an input and output system for grain, GrainSense Silo will continuously extract a sample of the grain from the connected system and perform a real-time and online quality analysis. Key values can be viewed on the device's display, and measurement data is sent to GrainSense Cloud, allowing the user to see the results in real-time and make quality-based decisions. From the continuous grain flow, a grain sample is extracted to GrainSense Silo's dosing screw, which in turn feeds a steady grain flow through the unit's sensors. This silo version comes with an installation insert tailored for mounting inside the silo and a camera that detects green and broken kernels by using state-of-the-art camera technology and artificial network computing.

How does it work?

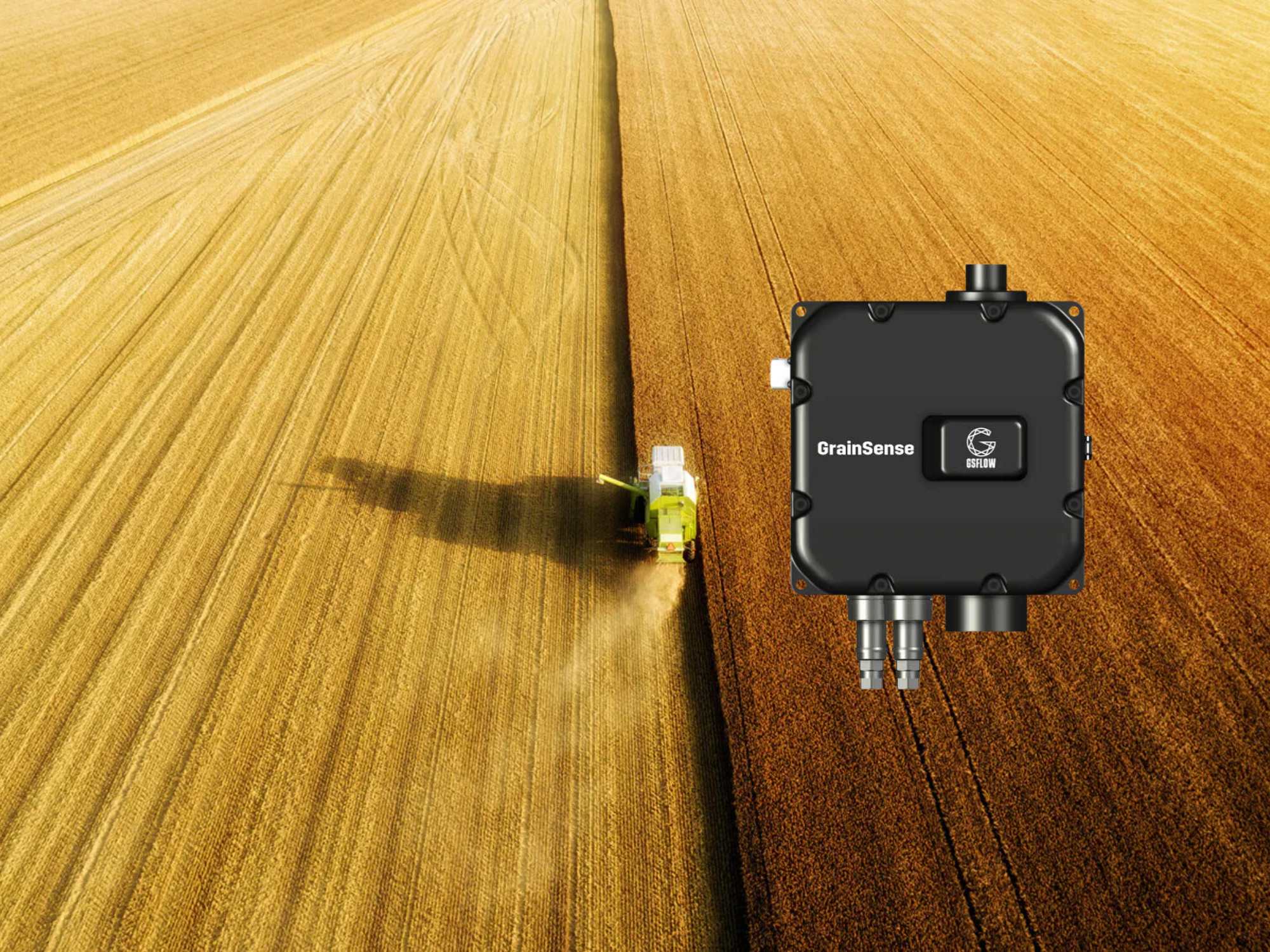

Via a grain entry and exit pipe system, grain is constantly flowing through the GrainSense Flow® sensor, where real-time analysis is performed. The measurement data is sent to the GrainSense Cloud, enabling the farmer to monitor the measured results in real-time and to make better decisions.

In grain farming, timing is crucial. To optimize harvesting, storage, feed use, and sales, detailed information about the crop's quality is required at every stage. In 2014, the technical research center VTT in Finland initiated a project that transformed laboratory equipment for NIR spectroscopy into a practical handheld format.

This gave birth to GrainSense as a spin-off from VTT at the end of 2014. Today, grain farmers, livestock breeders, silo operators, traders, and the food industry can quickly obtain accurate measurement results from GrainSense. This ensures that each crop is used for the right purpose, at the right price, and with optimal resource efficiency.

This gave birth to GrainSense as a spin-off from VTT at the end of 2014. Today, grain farmers, livestock breeders, silo operators, traders, and the food industry can quickly obtain accurate measurement results from GrainSense. This ensures that each crop is used for the right purpose, at the right price, and with optimal resource efficiency.