Smooth and precision-driven Vendro T 1020 - the key to even spreading and efficient drying!

This trailed tedder with 10 rotors and a 10.20 m working width provides maximum comfort for the operator, effectively accelerates the drying process, and delivers high-quality forage. It is perfectly suited for forage where achieving a higher dry matter content is desired or when there is a need to quickly dry wet forage before the next rain arrives. It is equipped with transport wheels, making it ideal for use with small tractors that have limited lifting capacity.

This trailed tedder with 10 rotors and a 10.20 m working width provides maximum comfort for the operator, effectively accelerates the drying process, and delivers high-quality forage. It is perfectly suited for forage where achieving a higher dry matter content is desired or when there is a need to quickly dry wet forage before the next rain arrives. It is equipped with transport wheels, making it ideal for use with small tractors that have limited lifting capacity.

Even drying and improved forage quality

As the harvesting window narrows, achieving optimal dry matter becomes challenging. KRONE's innovative OptiTurn rotors and 3D tines offer a unique solution with their three-dimensional shape, ensuring even and wide spreading that accelerates drying - improved water evaporation, increased air circulation, and superior forage quality. Reduce supplementary feeding, prevent feeding stress, and enhance animal health.

Adjust spreading angle to suit conditions

Whether it's silage in spring or hay in summer, different spreading angles are crucial for desired results. The Vendro hay tedder offers high processing for quick silage drying and gentle turning for hay. The angle is adjusted without tools - choose flat spreading (13° and 15°) for even hay distribution, or steep angles (17° and 19°) for optimal drying. The results are uniform drying and homogeneous distribution of dry material in your forage.

Timing is crucial in a narrow harvest window to save costs!

Being able to start tedding hay quickly when the weather allows is essential to avoid losses. With the Vendro, you're always prepared with minimal setup time, and maintenance is easy with just a few lubrication points. Krone's rotor gearbox also provides high reliability and stability, allowing you to work undisturbed during the forage season, save costs, and achieve high reliability.

Even drying with ground-following rotors

The OptiTurn rotor design is a crucial and specific feature of Krone's tedders. The unique design allows the rotors to generously overlap each other, and the OptiTurn tines can lift and evenly spread the crop with an optimal width for the best possible drying. The rotor arms are securely bolted to the rotors with an additional plate under the tine arm, providing a robust construction capable of handling large volumes of grass. Underneath each rotor, the rotor wheels with large tires are positioned extremely close to the rotor, ensuring optimal ground following without the risk of contaminants in the forage.

Perfectly poised

The Vendro T running gear which also carries the lights folds up and sits atop the rotors during work. With the running in this position, Vendro achievs a uniform distribution of the load which in turn translates into a uniform spread across the full work width.

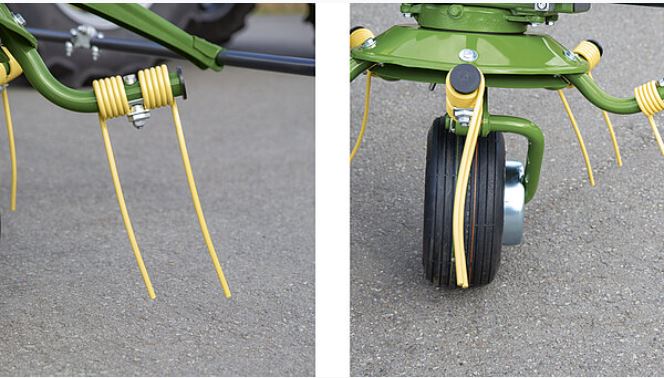

Smoother and more even spread with OptiTurn tines

The curved 3D tines with a thickness of 9.5 mm lift and toss the material to achieve clean and high-quality feed with even dry matter. The tines are attached with an eccentric plate allowing adjustment of the tine angle in three positions for optimal results in varying crops and terrain. To not miss any forage in the field, the tines are unevenly long in a pair, keeping them parallel above the ground, contributing to uniform wilting and optimal work quality in the new 3D tine system.

Designed to assist with the drying process

The OptiTurn fingers generously overlap to lift the crop without contamination and distribute it evenly. With the right spreading angle, the optimal width for quick drying and good feed quality can be achieved. Close to the rotors, support wheels are positioned to ensure optimal ground contour following and prevent feed contamination. This technique enhances productivity not only in the field but also in the milking parlor.

Reliable gearboxes for higher safety and longevity

The rotor gearboxes are mounted beneath the robust frame, where they are shielded from the strains of work and operation. They are both maintenance-free and lubricated with liquid grease, ensuring extended lifespan and trouble-free operations. Additionally, the gearboxes are independent of the frame, eliminating concerns about leaks, even in the toughest terrain.

Effortless angle adjustment for superior results

All Vendro models feature a hole system that allows you to easily adjust the spreading angle in four steps, ranging from 13° to 19°, without the need for any tools. A flat spread (13° and 15°) ensures even distribution and gentle hay turning, while steep angles (17° and 19°) provide optimal and more intense drying. This way, you can customize the machine's performance according to your specific preferences and keep the feed on the right side of the field edge to minimize losses.

Optimized reliability with OctoLink

The reliable OctoLink finger couplings are used in all Krone teddes. Each rotor is driven by a proven finger coupling with eight fingers, creating a strong and dependable connection within the driveline. Regardless of the angle, the power flow to the next rotor remains uninterrupted. The extremely robust finger couplings are completely lubrication-free, allowing you to save time on maintenance, increase productivity, and save money.

Optimal ground adaptation

The Vendro T is attached to the tractor's hydraulic arms and features a pivoting linkage point, allowing the machine to follow all ground contours and ensure optimal ground tracking.

Maintenance-free and protected driveline saves fuel

OctoLink couplings ensure seamless operation without the risk of driveline damage due to operator errors. The coupling isn't damaged if the driver accidentally forgets to disengage it when folding the machine! With eight fingers creating couplings, the driveline to the rotors is never broken, ensuring uninterrupted power transmission. The OctoLink coupling allows for low power losses in the driveline, resulting in fuel-efficient use. Take advantage of a maintenance-free driveline that minimizes service and maintenance requirements while maximizing its lifespan.

Streamlined folding with double-acting mechanism

Experience the convenience of Vendron's hydraulic folding and unfolding of side sections between working and transport modes. Sequential control during the folding and unfolding of side sections eliminates the need for sensors and cable wiring. The side sections are secured in the folded position with hydraulic locking valves. Enjoy improved control of the folding and unfolding process, and increased efficiency!

Hydraulic border spreading as standard

All 8- to 10-rotor machines have hydraulic border spreading control that is conveniently operated from the cab. The system brings the machine at an angle relative to the border so all material is kept in the field.

Compatible with smaller tractors for higher flexibility

Experience the benefits of the shortened mounting concept, placing the headstock closer to the tractor. This minimizes front axle relief and ensures compact dimensions. The headstock features pendulum suspension, providing stability and ease of movement. Enjoy an effortless operation with little to no lifting power required.

Anti-wrap guards for smoother workflow (option)

KRONE tedders come equipped with anti-wrap guards as standard, preventing long-stem crops from getting caught around wheels and support legs. This minimizes unnecessary stops and ensures a smooth and efficient workflow. For enhanced effectiveness, the anti-wrap guards can be supplemented with additional plates, providing extra protection and uninterrupted operation.

Work height adjustment for optimal rotor control

The Vendro T models offer easy work height adjustment for peak performance, even on uneven terrain. A front guide wheel is available as an option and can be mounted on the left, right, or both sides of the frame. Height is easily adjusted with a crank, allowing flexibility to adapt the machine precisely to ground conditions.

Ground following for even spread

The Vendro T is equipped with an oscillating two-point hitch that enables the machine to closely follow ground contours. This ensures optimal ground adaptation and an even spread across the entire working width, efficiently distributing material even on varied terrain.

-

Type of tedder Trailed rotortedder

-

Power requirements 55 hkr

-

Power requirements 44 kw

-

Working width 10,20 m

-

Transport widt 2,90 m

-

Transport height 3,70 m

-

Transport length 3,85 m

-

Weight 1810 kg

-

Hitching, cat Rear linkage, cat.II

-

Hitching, hydraulics 2xDA

-

Border spreading Yes, hydraulic

-

Adjustement spreading angle 13-19 degrades

-

Numbers of rotors 10

-

Numbers of tinearm/ rotor 5

-

Diameter rotor 1,37 m

-

Number of tines/ rotorarm 1

-

Tyres on rotorwheels 16x6.50-8, 16x9.50-8 (center)

-

Traffic lights

General

Dimensions

Frame

Rotors

Wheels

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.