Clean cuts and efficient forage conditioning with EasyCut R 320!

This mower is mounted and has a working width of 3.16 m. It forms a compact unit with the tractor and stands out with low power requirements and excellent ground following in all types of terrain.

This mower is mounted and has a working width of 3.16 m. It forms a compact unit with the tractor and stands out with low power requirements and excellent ground following in all types of terrain.

Improved yield and higher feed quality

Getting a rapid regrowth of the forage after the first cut is crucial for achieving a substantial second and, hopefully, third cut. While weather plays a significant role, the performance of the mower conditioner is equally vital. It's important to have a mower conditioner that provides clean cuts instead of tearing, which can damage the surface and hinder the forage's ability to recover. With Krone's SmartCut technology, grass is cut with a larger overlap, and changing blades is quick, resulting in clean cuts and higher yields.

Let technology assist you in achieving top-notch forage!

Spotting all the obstacles hiding in the forage can be challenging. That's why this machine is equipped with collision protection called SafeCut, which shields the machine from damage caused by rocks or branches. The integrated support arm protection reacts swiftly, halting affected cutter discs to minimize downtime and get back to work promptly. This system can save you costly and time-consuming repairs, especially when timing is crucial to getting top value for your feed.

Leak-proof and robust cutterbar for minimal maintenance

Krone's EasyCut machines require minimal maintenance thanks to their lifetime lubrication, durable construction, and large gears designed to minimize wear. This reduces both the time and cost of maintenance while ensuring the mower conditioner lasts longer. In the Farmers First Maintenance App, you'll find ready-made maintenance plans that help reduce downtime, extend the machine's lifespan, and improve its resale value.

Maximum regrowth with gentle cutterbar

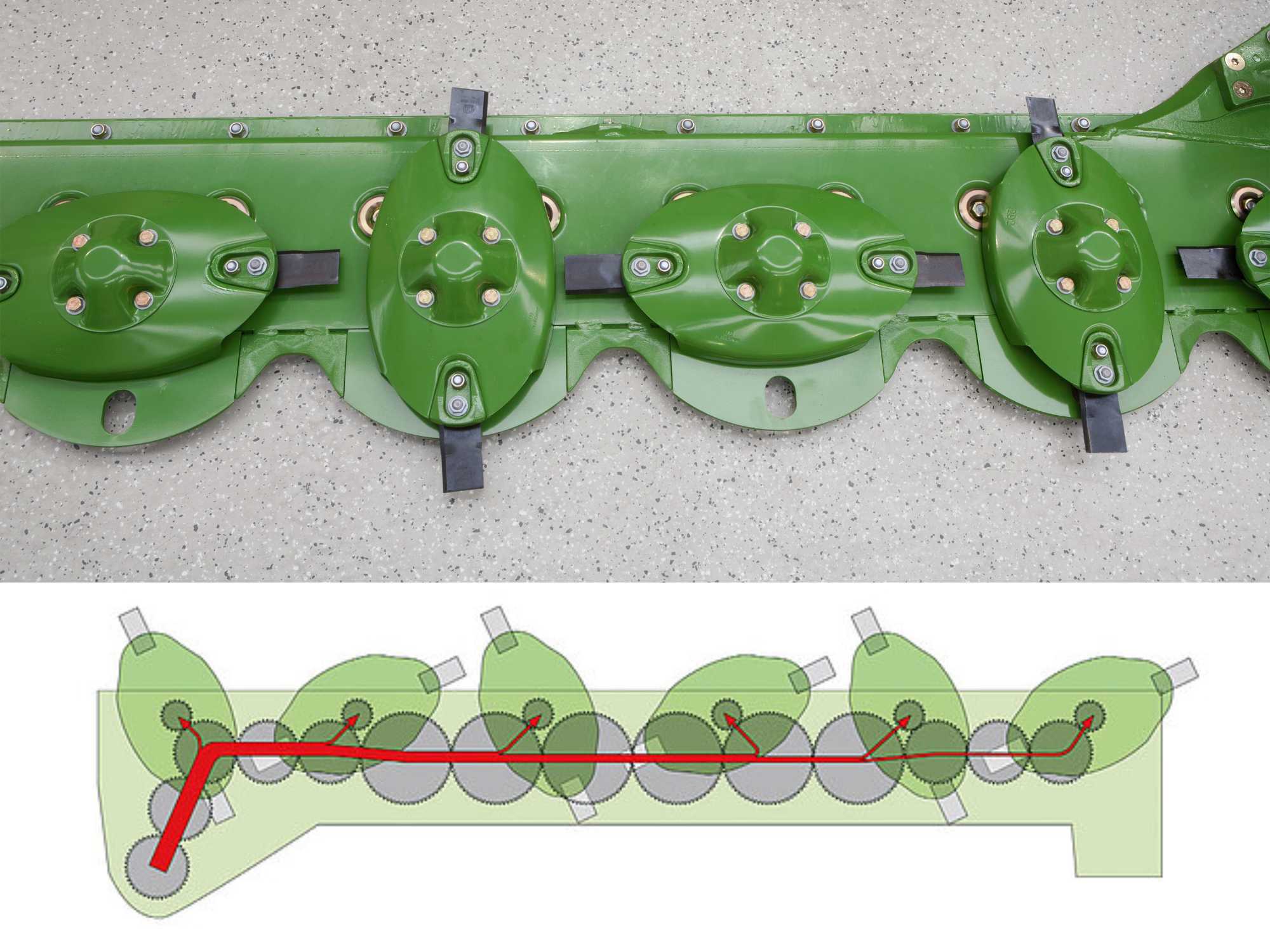

In order for the pasture to recover and grow rapidly after the first cut, a gentle initial mowing is required. The Krone cutterbar is the heart of the machines and is built to last, with a robust welded construction and permanent lubrication. Its massive gears impress with quiet and reliable operation under continuous load, contributing to superior cutting quality and maximum longevity.

Simple and fast blade changes

The key to clean cuts is quality blades, which is why Krone has developed a blade change system that is both simple and fast. This ensures that you can always achieve results with clean cuts in the field, promoting healthy and rapid regrowth. When it's quick to change the blades, it becomes easier to do so as often as needed, ensuring optimal performance of the mower.

Safe field cutting and quick field repairs with SafeCut

Avoiding stones and branches hidden in the field can be challenging. That's why Krone equips its mowers with the SafeCut system, safeguarding your machine from unexpected obstacles, reducing downtime, and repair needs. SafeCut's unique features, such as pins that release under overload and self-lifting discs, prevent chain reactions and simplify on-field repairs. With this collision-resistant design and wear-resistant components, Krone's SafeCut system ensures a secure forage harvest.

Smooth and consistent crop flow without blockage

The EasyCut R models are equipped with a self-supporting protective cover that allows the crop to pass smoothly through the machine without getting stuck anywhere. These disc mowers can cut and follow the ground surface even on sloping fields and challenging terrain without interruptions, resulting in consistent and impressive outcomes.

Flexible mowing with adjustable drawbar springs

The EasyCut R-models are equipped with adjustable drawbar springs that enable offset positioning behind the tractor. This allows for cutting at full width on any track width, even on side slopes, and in combination with a front mower.

The best contouring in all types of terrain

The hydraulic and the mechanical suspension springs are extremely responsive and provide perfect cuts even in undulating terrain and at high forward speeds. This is the first step in making clean and high-quality forage and a requirement for a fast and uniform re-growth. The kinematics between the coil spring and the main beam maintain a nearly consistent ground pressure, even in undulating terrain.

Efficient drivetrain for reliable performance and protection

A drivetrain with constant speed and efficient power transmission ensures reliable performance. The power is smoothly transferred through a friction driveline consisting of axles and gears. The drive shaft is equipped with friction clutches positioned between the main gearbox and the cutter bar, providing maximum protection for the cutter bar, universal joints, and the tractor's power take-off.

Safe road travels

The compact transport dimensions are due to the fact that the mower-conditioner tilts toward the center of the tractor, allowing for optimal weight distribution and visibility. The unit is hydraulically folded using the double-acting piston to 124° for improved road stability and visibility. All versions of the EasyCut R are foldable, facilitating a seamless transition between working and transport modes. When the machine is switched to transport mode, the protective cover is folded back and down to reduce the transport height.

Improved machine safety with collision protection system!

Integrated into the suspension system, the standard collision protection system is available on all supported mowing units. The collision protection system provides peace of mind when working alongside boundaries, fences, and hedges, and suddenly encountering an obstacle. When the system triggers a collision, the mower bar swings backward and upward to clear the obstacle. Once the obstacle is passed, the mower bar automatically returns to the working position. The conventional mechanical collision protection is a highly reliable system consisting of an adjustable coil spring and a lock.

Optimal performance and ground following, even on rocky fields!

The slidig skids are mounted under the mower bar, ensuring smooth forage flow while protecting the grass surface. Made from hardened steel, they are durable and help maintain the mower bar's parallel alignment with the ground, ensuring exceptional cutting precision. Various sliding skid options are available for different terrains or cutting heights, including wear plates and those suitable for high-cutting situations. The sliding skids provide the reliability needed for achieving optimal performance and ground-following capabilities in your mowing operations.

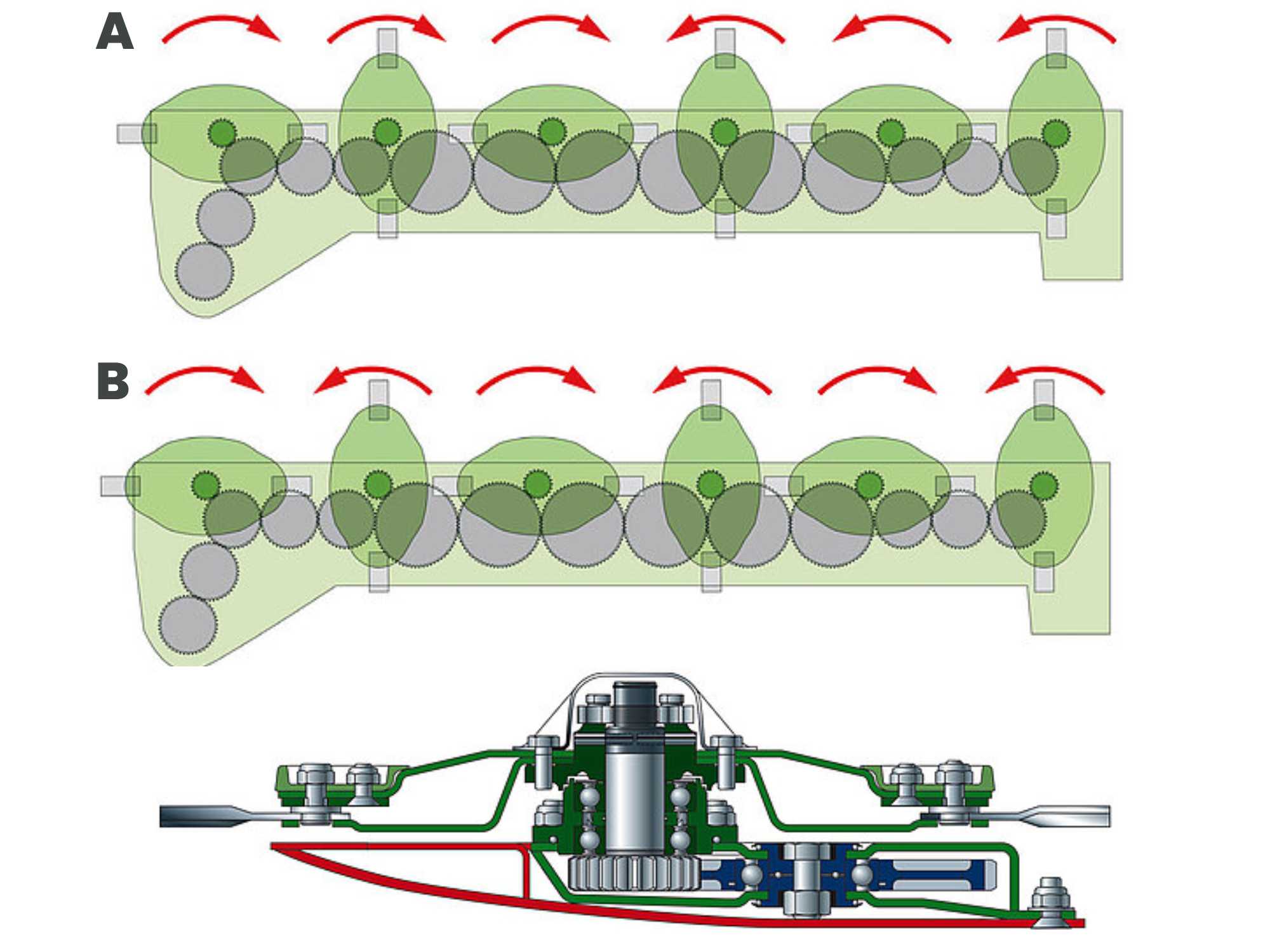

Enhanced forage efficiency with SmartCut

Experience optimized forage flow and seamless overlapping with the SmartCut technology. Our flying knife cut and increased disc overlap guarantee top-notch cutting quality. The eccentric drive allows versatile rotation options—swathing for center-focused rotation (A) or wide spreading with discs turning in pairs (B). These machines come with a standard spare blade drawer. The wedge-shaped cutterbar ensures adaptable settings for short or long stubble, providing reliable performance and a clean cut for diverse crops.

Protect the ground surface without compromising with the cutting quality!

The DuoGrip suspends the mower in its centre of gravity and guides it via two arms. This design allows the cutterbar to follow the ground contours even more accurately for a better protection of the sward. This way, the machine produces high-quality forage even in difficult conditions.

Reliable and robust design with the fully welded cutterbar

KRONE uses welding robots and CNC technology to manufacture their cutterbars to the highest quality standards. Thanks to the fully welded and permanently lubricated construction, leakage is prevented, and maintenance needs are significantly reduced. This maintenance-free design ensures that the cutterbar retains its shape and function even after many years of use. Through a meticulous manufacturing process, permanent lubrication is ensured, eliminating the need for oil changes.

-

Type of mower Rear mounted mower conditioner

-

Number of sections 1

-

POwer demands PTO 68 hkr

-

Speed PTO 540 rpm

-

PTO speed option 1000 rpm

-

Working width 3,16 m

-

Transport height 3,90 m

-

Weight 840 kg

-

Mechanic system with springs

-

Demands hydraulics (LS, DA, SA) 1xSA

-

No of discs 5

-

No of blades/disc 2

-

No of Tophats 2

-

Quick change blades std

-

Safesystem discs

-

Skids Yes. additional ones as option

-

With conditioner

-

Wide spreading deflector boards

-

ISOBUS

-

Swathing

General

Dimensions

Frame

Cutterbar

Conditioner

Swathing

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.