Här kan du se våra färdiga paket och är du inloggad ser du rätt pris istället för listpris. Har du andra önskemål om maskinutrustning? Kontakta våra produktspecialister för skräddarsydda lösningar.

Premos - A flexible, high-capacity pelleting press!

Krone's Premos pelleting press functions both as a mobile unit, producing pellets directly from straw in the field, and as a stationary pellet press with straw bales. It boasts an impressive throughput of up to 5000 kg per hour, producing high-quality, fiber-rich pellets suitable for use as bedding, animal feed, and fuel.

Krone's Premos pelleting press functions both as a mobile unit, producing pellets directly from straw in the field, and as a stationary pellet press with straw bales. It boasts an impressive throughput of up to 5000 kg per hour, producing high-quality, fiber-rich pellets suitable for use as bedding, animal feed, and fuel.

Use directly in the field or as a stationary mill

The Premos 5000 is the first pellet press to collect crops like straw, hay, or alfalfa directly from the field and compress them into structural pellets. The finished product is then transferred to a container. As a stationary machine, it can be used year-round to convert straw bales into straw pellets. In this setup, it's equipped with a bale breaker, integrated feeding table, and automatic bale twine removal.

High throughput and low power requirement

The Premos can produce up to 5 tons of pellets per hour and utilizes only high pressure to make the pellets. No additives are used, as the material is not chopped before pelleting, preserving its structure. This explains the significant savings in power required for this machine compared to traditional pellet presses.

High-quality pellets

Premos 5000 preserves the natural structure of the material by utilizing high pressure without additives, enhancing the pellets' ability to absorb moisture. This is ideal when the pellets are used as feed since no other substances are added, and it's easy to adjust the pellet length to suit various purposes. Additionally, it features a water reservoir used to regulate the moisture level in the material to optimize pellet quality. With the built-in cooling system, the temperature of the finished pellets is reduced, ensuring high-quality pellets throughout the process and storage. Vegetable oil is used during the pelletizing process startup, thus Premos 5000 also includes an oil reservoir.

Cost savings and reduced inventory

Pellets offer a range of advantages compared to traditional straw, especially concerning cost savings and inventory management. Their compact form takes up significantly less space, reducing the need for large storage areas and thus lowering storage costs.

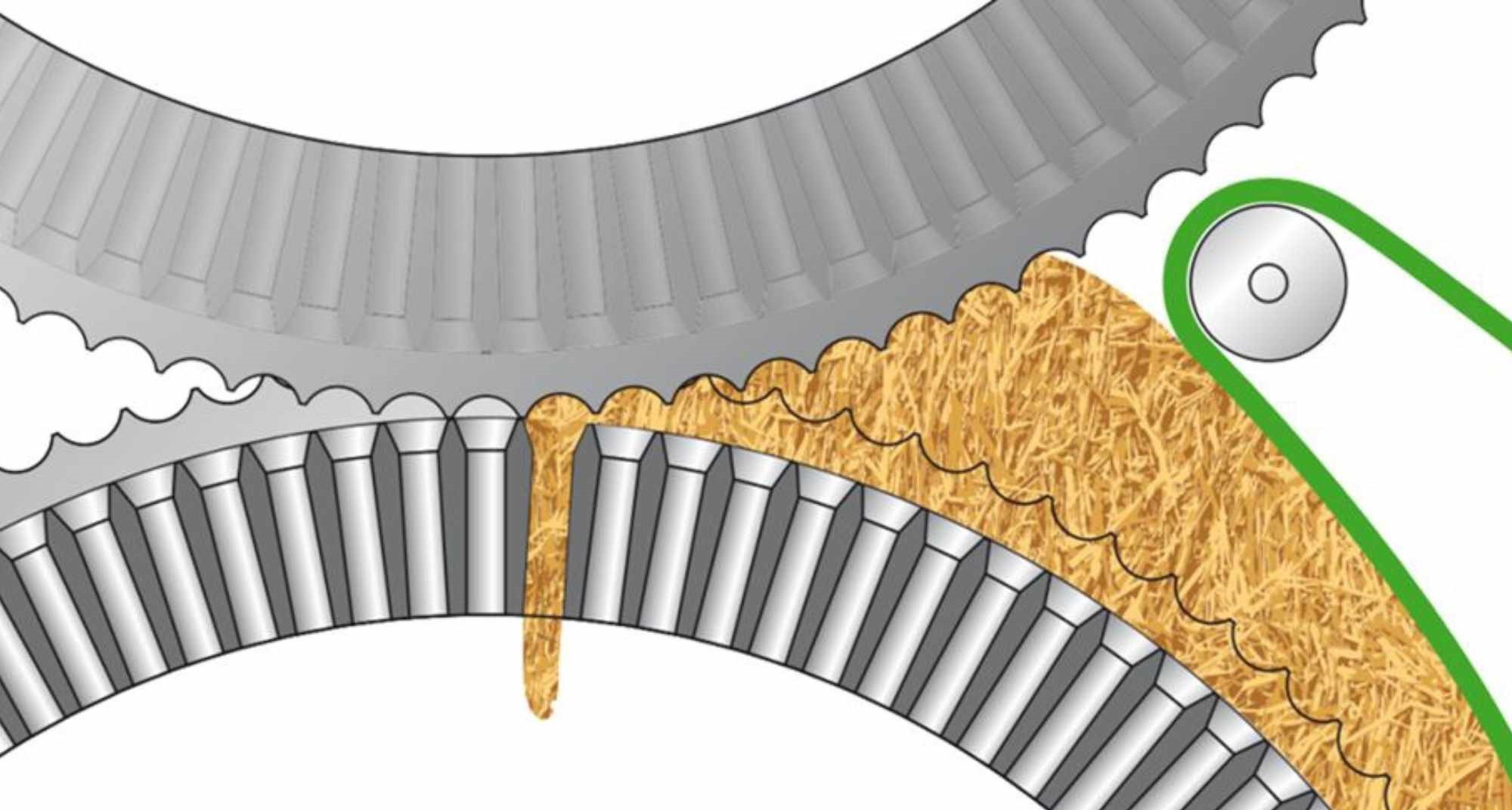

High-pressure pressing

The straw is pressed using two counter-rotating pellet press rollers with alternating patterns of teeth and holes. This enables a uniform and reliable processing of the material, where the teeth on one roller grip into the holes of the other, create a powerful pressure of up to 2,000 bar with controlled temperatures up to 100 °C. This meticulous process ensures that your pellets meet the highest quality standards.

Adjustment of pellet length

As the material passes between the two rollers, it is pressed into the 16 mm wide holes and then continues into the inside of the rollers. The diameter of the pellets remains constant as it is determined by the size of the hole, but the length of the pellets can be adjusted between 15 mm and 40 mm by adjusting the distance between the spacer and the pellet press roller. This flexibility allows for the creation of pellets with different lengths to suit various purposes.

Highest quality pellets

The screws inside the rollers transport the finished pressed pellets to a conveyor, which then feeds the pellets through a sieving drum. Here, dust and other impurities are separated from the pellets, and the excess material falls back to the pellet press rollers to be pressed into pellets again, while the finished pellets are transported to the container. This results in pellets of the highest quality, ready to be used as bedding, feed, or fuel.

Storage container and discharge

The pellets are transported to a spacious container with a capacity of 9 cubic meters. After undergoing a process of high pressure and heating, the pellets are cooled by a fan as they reach the container. When the container is full, which is also monitored by a weighing system, the pellets can be easily discharged via a conveyor on a retractable arm.

Efficient and uniform material collection

The wide and camless pickup, with a width of 2.35 meters, ensures a clean and efficient collection of the crop. A pre-processing roller placed in front of the pickup guarantees a smooth flow even at low driving speeds, contributing to smooth operation and a consistent flow of the crop.

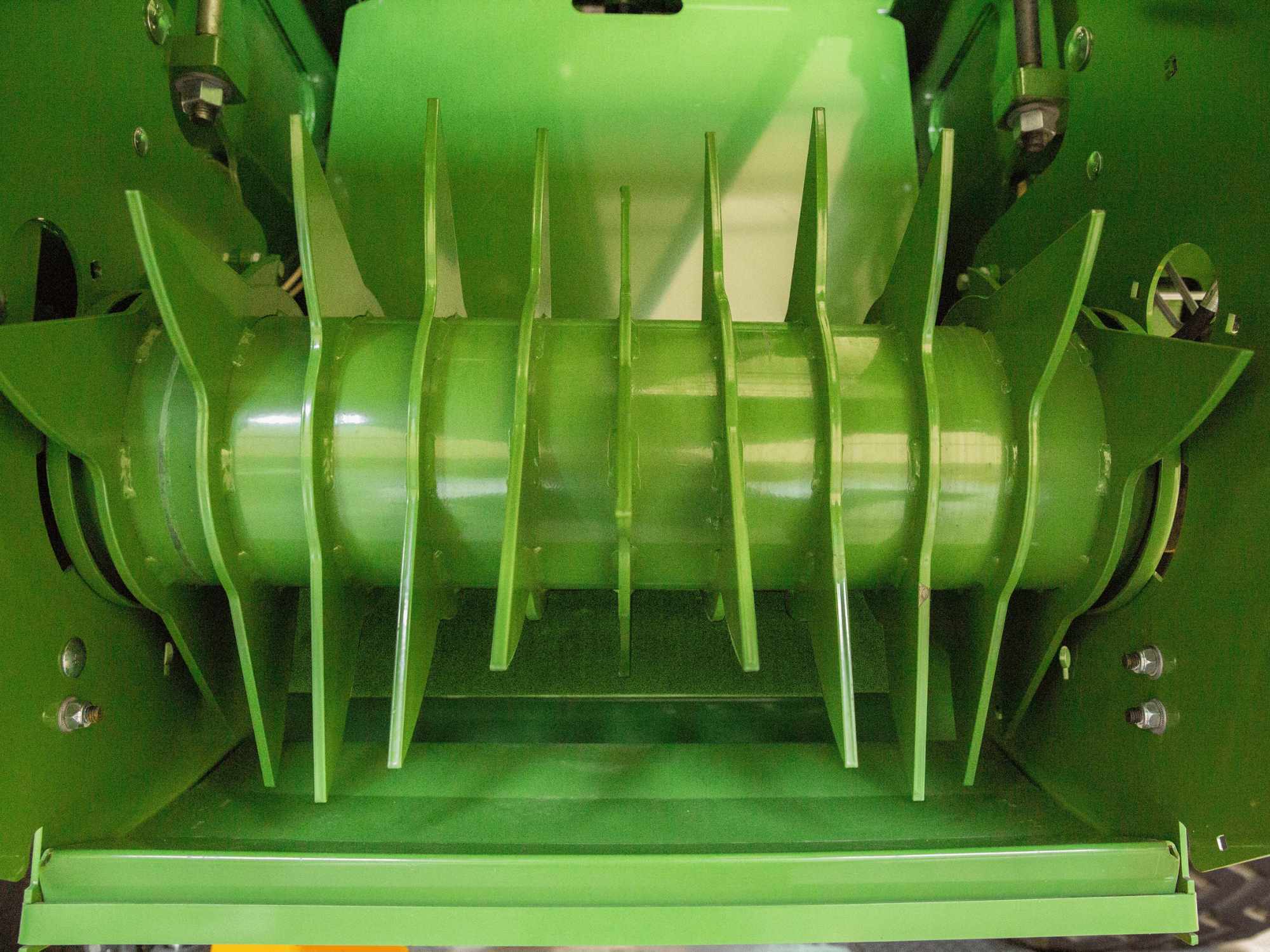

Feeding rotor and feeding belt

An 800 mm wide rotor continuously feeds the material from the pickup to the feeding belt for smooth handling. Any foreign objects are sorted out and collected in a stone trap located behind the rotor, while the material continues to the pellet press rollers for further processing.

Water and oil dispenser

The dispenser carefully regulates the amount of water or oil to a series of nozzles that gently spray the liquid onto the pellet press rollers. Through this process, moisture levels and adhesive properties of the material are optimized, which is crucial to ensuring a consistently high quality of the pellets.

Cooling system ensures quality

During the pelletizing process, temperatures of up to 100°C are generated. To prevent deterioration of pellet quality during storage, a fan is used to cool down the pellets. Air is blown into the container through a double floor, effectively lowering the temperature and ensuring that the pellets maintain their high quality over time.

Effective feeding table (optional)

The stationary Premos model is equipped with a feeding table of 7.5 meters and featuring a hydraulic folding mechanism for convenient use. When the bale is placed on the table, it is forwarded by two chains with hooks before being processed by the shredding rotors, prior to the straw being fed into the pellet press. This seamless process ensures a smooth and efficient handling of the material for further processing.

Automatic bale twine removal

The bale twine is automatically removed when it reaches the end of the table, while a triangular blade cuts the twine at the base. A bunch hook, positioned above the bale, guides the twine towards a rotating spool which then winds up the twine and removes it from the bale before the straw is fed into the pelleting press.

Bale shredder provides a uniform flow into the pelleting press

The bale shredder consists of four hydraulic rotors equipped with blades and guide plates. As the bale passes over them, the blades cut the straw and are then pulled out by the toothed plates. To ensure a uniform distribution of the material across the working width, additional spring plates are placed behind the rollers.

Smooth folding for road transport

To easily move between locations, the feeding table smoothly folds up on the machine's side using a hydraulic mechanism. This reduces the transport width to less than 3 meters, allowing for quick and easy movements on the road.

Feeding pellets to animals

Pellets made from hay, alfalfa, and straw are excellent as basic feed for animals. Studies show that structural pellets have significantly lower levels of pathogens and mold compared to hay from traditional bales. This provides high-quality nutrition suitable for feeding animals.

Animal welfare and natural behavior stimulation

Structural pellets are dust-free and sterile, making them an excellent resource for promoting animal well-being. They can be used in small quantities in pig farming as enriching material to stimulate animals' natural behaviors. In this way, structural pellets support animal welfare initiatives and foster a comfortable environment for animals to explore and thrive in.

Comfortable bedding for larger animals

Structural pellets has an impressive ability to absorb liquid, with up to 4 liters of water absorbed per kilogram of straw pellets. This high absorbent capacity makes straw pellets the optimal choice for creating a comfortable and clean bedding for indoor cattle. The improved environment results in cleaner cattle and promotes better animal health. Additionally, the use of pellets reduces the need for bedding material compared to traditional straw, making it a cost-effective alternative for farmers.

Ideal for horses

Straw pellets are the ultimate choice for keeping horse stalls dry, thanks to their impressive liquid-absorbing ability. The disinfectant properties of the pellets help control pathogens that can cause common fungal infections. Furthermore, straw pellets are dust-free, reducing the risk of respiratory issues for horses and creating a healthier environment for them to live and thrive in.

Enhanced animal hygiene

The high absorbent capacity of straw pellets also provides benefits in poultry farming. By keeping the floor cleaner with structural pellets as bedding material, not only makes the animals' legs remain clean, but so do the nests and the eggs laid in them. Additionally, it reduces the amount of ammonia pollution in poultry houses, creating a healthier and more comfortable environment for the animals to live in.

A sustainable fuel

With 2.5 kg of straw pellets, you can replace 1 liter of heating oil. Globally, there are approximately 800 million tons of straw available for use as fuel. Each year, around 30 million tons of straw are harvested in Germany, of which 8–13 million tons can be used as a renewable energy source. Straw thus has significant, yet untapped potential to make a substantial contribution to climate protection as a "renewable fuel," reducing CO2 emissions.

Terminals

Premos can be easily operated from several user-friendly operator terminals. Here, operators control machine functions and input settings.

- DS 500 – Standard operator terminal with a 5.7" color screen.

- CCI 800 – User-friendly operator terminal with an 8" touch screen.

- CCI 1200 – User-friendly operator terminal with a 12" touch screen.

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.