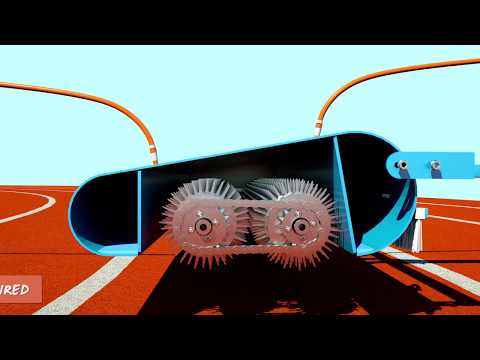

Since 1985, the Dutch company GKB has developed user-oriented and innovative machines that are adapted to all types of sports surfaces. A compacted artificial grass pitch is unpleasant to play on and this problem must therefore be solved quickly. Loosening the pitch with a standard tooth bar will cause some wear: the fiber tips will split. If, on the other hand, you opt for the Aerator, this problem will not occur. Your complete synthetic turf system can be decompacted with an Aerator. The Aerator is equipped with tooth rollers, which are coupled to each other with a light toothing. Due to this toothing, the teeth of the roller transmit a slight prying effect. As a result, the compacted package breaks open, so that the sport-technical properties are brought back to the bottom. The field will feel like new again!

-

How does the machine work?

- Connect the machine to your tractor. In which way depends on the chosen model: this can be via a towing eye, or via the three-point coupling.

- Simply drive; the Aerator does not stop and follows your course.

- Gradually, the compacted artificial grass pitch is loosened.

- Processing speed 10 km/h.

- Follows you and don’t stop at the end of the field

- Slight prying action breaks open compacted package.

- Geared rollers coupled together.

- Available in version with 4, 6 or 8 tooth rollers.

- Weighting by means of metal plates.

- Easy to couple with towing eye or three-point coupling (cat I or II).

- Optional: adjustable front and rear roller set.

-

The features of the Aerator

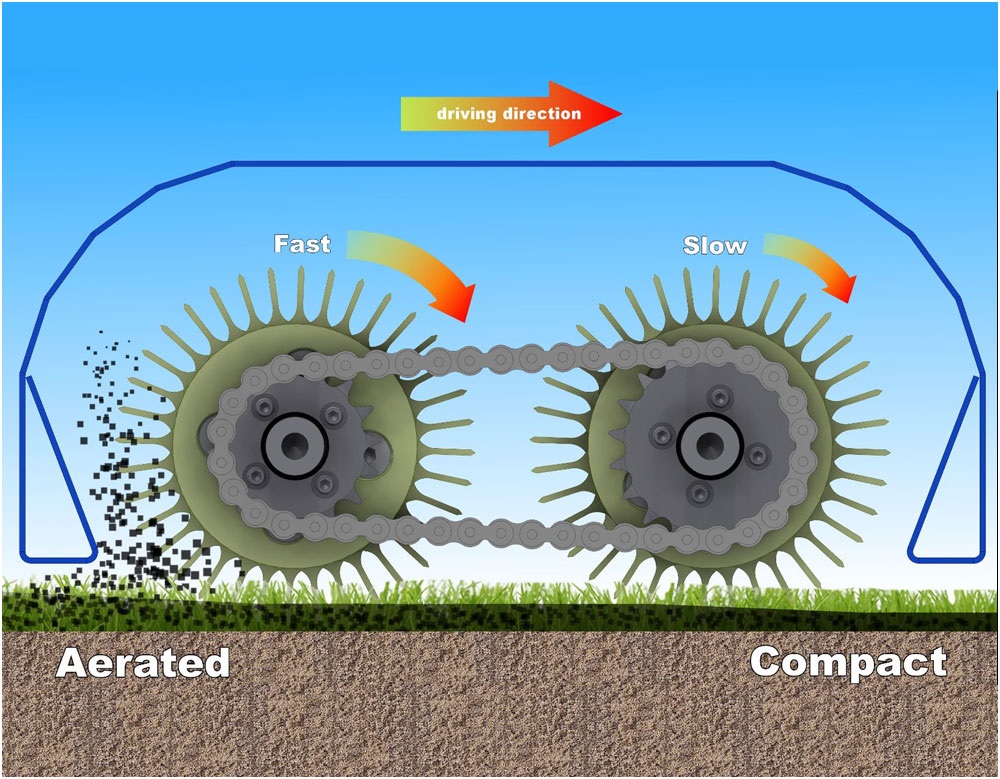

Aerator Toothed gear rollers

Aerator has two toothed gear rollers, the front roller loosens and lifts the infill granulate while the rear roller deposits the infill granulate back.

Aerator Extra Weight Plates

Weights up to 90kg can be mounted on the Aerator. This is to increase ground pressure and loosen packed granules more easily.

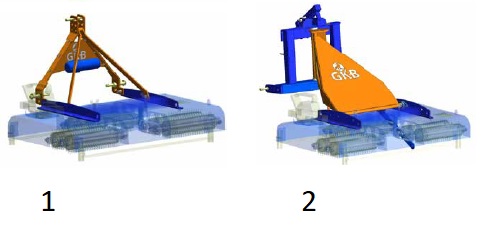

Aerator The towing unit

In Picture 1, the Aerator is equipped as standard with a static Rear 3P lift cat I-II.

In Picture 2, the Aerator is equipped rear 3P lift cat I-II, with a hinge-like solution that follows your tractor in the turns.

Why GKB

The machines that we develop are reliable, robust machines. We owe this fact to the fact that we are still working with the machines as well. We know what the man who does the work requires to operate in a good and efficient manner. Therefore, we are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you should purchased it.

GKB sustainability

At GKB Machines we feel strongly about sustainability, as a family-owned company we aim for a sustainable company with a positive future prospect. That we do not just stick to words is evident from the fact that we are producing our machines energy neutral.

Sustainability is also highly important during the development of the machines. We develop the machines from the experience we have established from our contractor division. Every GKB Machine must satisfy the high-quality requirements that we impose. A sustainable, reliable and robust machine is the foundation for your operation. Since our contractor division is used to receiving these type of machines, you might also expect this from us.

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

Sustainability is also highly important during the development of the machines. We develop the machines from the experience we have established from our contractor division. Every GKB Machine must satisfy the high-quality requirements that we impose. A sustainable, reliable and robust machine is the foundation for your operation. Since our contractor division is used to receiving these type of machines, you might also expect this from us.

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

-

Working width 1500 mm

-

Working depth 0-35 mm

-

Working speed 7-12 kmh

-

Hitch Rear 3P lift cat I-II

-

Power requirement 20-40 hkr

Repairing

GKB Machines is part of the GKB Group. Since 1985 GKB Machines, as a separate division, is engaged with the development of innovative maintenance machines for sports pitches.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.

GKB Machines feel strongly about sustainability, as a family-owned company they aim for a sustainable company with a positive future prospect. That they do not just stick to words is evident from the fact that they are producing the machines energy neutral.

Sustainability is also highly important during the development of the machines. GKB develop the machines from the experience they have established from their contractor division. Every GKB Machine must satisfy the high-quality requirements that they impose. A sustainable, reliable and robust machine is the foundation for your operation. Since their contractor division is used to receiving these type of machines, you might also expect this from GKB.

"The Worker is King"

The machines that GKB develop are reliable, robust machines. They owe this fact to the fact that they are still working with the machines as well. GKB knows what the man who does the work requires to operate in a good and efficient manner. Therefore, they are using a new slogan: “The Worker is King”. This is important, since only in this way the machine can deliver pitches that look great. The reason why you purchased it.