The agile and precision-accurate KWT tedder - the key to even spreading and efficient drying!

These towed hay tedders with 12 to 18 rotors and a working width of 13.10 to 19.60 meters provide maximum comfort for the operator, effectively shorten the drying process time, and deliver high-quality forage. Perfect for forage where a higher and more consistent dry matter content is desired.

These towed hay tedders with 12 to 18 rotors and a working width of 13.10 to 19.60 meters provide maximum comfort for the operator, effectively shorten the drying process time, and deliver high-quality forage. Perfect for forage where a higher and more consistent dry matter content is desired.

Even drying and improved forage quality

As the harvesting window narrows, achieving optimal dry matter becomes challenging. KRONE's innovative OptiTurn rotors and 3D tines offer a unique solution with their three-dimensional shape, ensuring even and wide spreading that accelerates drying - improved water evaporation, increased air circulation, and superior forage quality. Reduce supplementary feeding, prevent feeding stress, and enhance animal health.

Adjust spreading angle to suit conditions

Whether it's silage in spring or hay in summer, different spreading angles are crucial for desired results. The KWT hay tedder offers high processing for quick silage drying and gentle turning for hay. The angle is adjusted without tools - choose flat spreading (13° and 15°) for even hay distribution, or steep angles (17° and 19°) for optimal drying. The results are uniform drying and homogeneous distribution of dry material in your forage.

Timing is crucial in a narrow harvest window to save costs!

Being able to start tedding hay quickly when the weather allows is essential to avoid losses. With the KWT, you're always prepared with minimal setup time, and maintenance is easy with just a few lubrication points. Krone's rotor gearbox also provides high reliability and stability, allowing you to work undisturbed during the forage season, save costs, and achieve high reliability.

Even drying with ground-following rotors

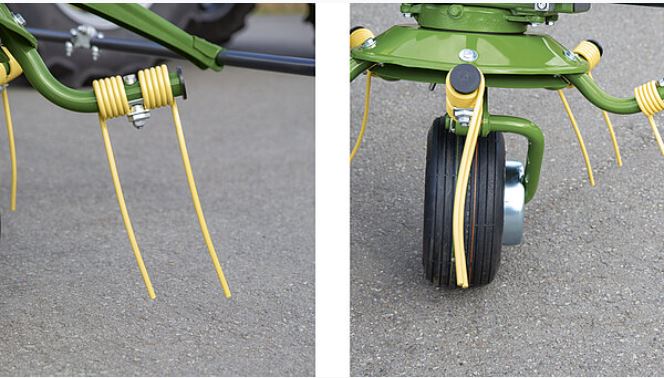

The OptiTurn rotor design is a crucial and specific feature of Krone's tedders. The unique design allows the rotors to generously overlap each other, and the OptiTurn tines can lift and evenly spread the crop with an optimal width for the best possible drying. The rotor arms are securely bolted to the rotors with an additional plate under the tine arm, providing a robust construction capable of handling large volumes of grass. Underneath each rotor, the rotor wheels with large tires are positioned extremely close to the rotor, ensuring optimal ground following without the risk of contaminants in the forage.

Smoother and more even spread with OptiTurn tines

The curved 3D tines with a thickness of 9.5 mm lift and toss the material to achieve clean and high-quality feed with even dry matter. The tines are attached with an eccentric plate allowing adjustment of the tine angle in three positions for optimal results in varying crops and terrain. To not miss any forage in the field, the tines are unevenly long in a pair, keeping them parallel above the ground, contributing to uniform wilting and optimal work quality in the new 3D tine system.

Reliable gearboxes for higher safety and longevity

The rotor gearboxes are mounted beneath the robust frame, where they are shielded from the strains of work and operation. They are both maintenance-free and lubricated with liquid grease, ensuring extended lifespan and trouble-free operations. Additionally, the gearboxes are independent of the frame, eliminating concerns about leaks, even in the toughest terrain.

Designed to assist with the drying process

The OptiTurn fingers generously overlap to lift the crop without contamination and distribute it evenly. With the right spreading angle, the optimal width for quick drying and good feed quality can be achieved. Close to the rotors, support wheels are positioned to ensure optimal ground contour following and prevent feed contamination. This technique enhances productivity not only in the field but also in the milking parlor.

Optimized reliability with OctoLink

The reliable OctoLink finger couplings are used in all Krone teddes. Each rotor is driven by a proven finger coupling with eight fingers, creating a strong and dependable connection within the driveline. Regardless of the angle, the power flow to the next rotor remains uninterrupted. The extremely robust finger couplings are completely lubrication-free, allowing you to save time on maintenance, increase productivity, and save money.

Maintenance-free and protected driveline saves fuel

OctoLink couplings ensure seamless operation without the risk of driveline damage due to operator errors. The coupling isn't damaged if the driver accidentally forgets to disengage it when folding the machine! With eight fingers creating couplings, the driveline to the rotors is never broken, ensuring uninterrupted power transmission. The OctoLink coupling allows for low power losses in the driveline, resulting in fuel-efficient use. Take advantage of a maintenance-free driveline that minimizes service and maintenance requirements while maximizing its lifespan.

Optimal spread with adjustable spreading angle

The Tine control system is designed to provide excellent spreading under all conditions. The tines are attached to the tine arms with an eccentric plate, allowing adjustment to one of three spreading angles. This adjustability ensures optimal spreading and efficiency regardless of field conditions, resulting in better outcomes and higher productivity.

Border spreading system

The manual border spreading system is easy to use and offers a smooth solution for changing the spreading direction. With a mechanical lever, you can turn all the rotor wheels to the left or right, giving you full control over the spreading direction. This user-friendly system allows you to quickly and easily adjust the spreading to achieve the best possible results, saving time and effort. The border spreading system can also be optionally hydraulic.

Boundary spreading with swath curtain

The swath curtain is hydraulically controlled and is an excellent choice for those who want maximum precision in boundary spreading. This system ensures that the crop stays within the field boundary and is not thrown outside.

Robust frame construction

The robust frame of the tedders is designed to handle the stresses of large working widths. The frame beams used are built to withstand tough conditions, and the closed guard bar with angled cross braces provides extra stability. This sturdy construction not only meets safety standards but also relieves the side sections and pivot points to create a more durable and reliable machine.

Use the smaller tractor

The spiral spring connects the top link attachment to the transport frame. When the rotors are in the turning position, the spring presses on the frame, compensating for negative draft load (the draft lifts). This allows you to use this model even with a smaller or lighter tractor, providing greater flexibility and saving both time and money.

Height control adjustment

The height of all tines is adjusted with a crank in the center of the machine for quick and easy adaptation to varying conditions.

Smooth working depth control with hydraulic top link

The hydraulic top cylinder is in float position during operation, providing optimal conformity to the ground contour and maintaining the set working height. When turning and transitioning to transport mode, the hydraulic cylinder raises the entire frame to approximately a 90° position. This facilitates smooth movement and ensures that the machine always operates efficiently and precisely.

Automatic folding

Both the KWT 1300 and the high-capacity models KWT 1600 and KWT 2000 offer convenient automatic and sequence-controlled folding directly from the driver's seat, reducing the risk of operator error. As a final step, a separate valve smoothly raises and lowers the side sections to turning or working position, making your work both easier and safer.

High stability with wide transport wheel

The wide transport wheel ensures quiet operation and good stability on the road, even on uneven surfaces. There is also the option to choose wider tires, which offer several advantages. Flotation tires on the transport chassis provide smoother operation in wet terrain and reduced soil compaction due to a larger contact area. This makes transportation both more comfortable and gentler on the ground.

Precise steering

The lower arms on the chassis provide very precise steering of the rotors. The design of the wheels on the transport chassis allows for easy turning and functions as a leading support wheel for active control of the tines' contour. This ensures that the rotors follow the ground contours accurately, resulting in a smoother and more efficient spreading.

Hydraulic suspension for the transport axle

The transport axle on the KWT 1300 can optionally be equipped with hydraulic suspension. In the turning position, the KWT 1300 carries most of its weight on the transport axle, providing good tracking and stability during turns. In the working position, the lift cylinder transfers the weight from the frame and axle to the rotor wheels and top link, reducing the load on the transport wheels and minimizing the risk of slippage in sharp turns. Despite this configuration, the transport wheels still function as support wheels in front of the rotors – a smart design that prevents damage to the grass sward and contamination of the crop.

High precision and ground adaptation

This machine is equipped with double joints on the frame and elongated holes for the lift arms, ensuring it follows the ground contours flexibly and unhindered by the transport chassis. This well-thought-out design guarantees precise and clean work, even on hilly fields.

Forced steering

The pivoting KWT 1600 and KWT 2000 tedders are equipped with an advanced steering system that operates via the three-point top link. By adjusting the steering, the track width of the transport axle is automatically adjusted to match the tractor's wheel track or the rotor wheels. This adjustment occurs automatically and in sequence when the machine switches between transport, turning, and working positions, ensuring smooth and efficient operation.

Safe and comfortable road transport

For safe and comfortable road transport, the machine is equipped with high-reflective side curtains and efficient lighting. This enhances traffic safety, especially during night driving and when passing through traffic intersections.

Responsive turning radius that protects the grass

In working mode, the wheels on the transport chassis are steered in relation to the rotor wheels to perfectly match their turning radius. This prevents slippage during turns, protects the grass sward, and makes it easier to maneuver along curved field edges, resulting in even and efficient spreading. It also makes it easy to navigate through narrow gates and headlands, significantly facilitating your work.

Efficient hydraulic lift mechanism

The rotors are smoothly and hydraulically lifted using a lift mechanism, providing an impressive lift height both for transport and at headlands.

Reduction gearboxes for night swathing (optional)

To prevent the crop from absorbing moisture during the night, one method is to create narrow "swaths" instead of having the crop spread out on the ground. To create narrow swaths, the rotor speed must be reduced. By using an optional gearbox that reduces the rotor speed, the rotor's rotation is slowed down, and the crop's speed through the rotors is reduced, allowing it to be placed in swaths behind the machine.

Effective anti-wrapping guards (optional)

To protect the wheels from sticky forage wrapping around them, optional plates can be attached to the wheel holders. These anti-wrapping guards are easy to install and help keep the wheels clean and free from debris, ensuring smoother and more efficient operation.

Spare wheels (optional)

Optional spare wheels are available in sizes 16x6.50-8 or 18x8.50-8. These are stored on a holder that comes with the wheel, allowing the spare wheel to be easily removed without tools.

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.