Efficient Swadro TS - the key to high productivity in forage harvesting!

This rake features two to three rotors that place the swath beside the tractor and offers a working width ranging from 6.2 m to 7.4 m for single swaths. For the Twin-models a working with of 7.6 m to 8.2 m is possible while making two smaller swaths. It's designed with intelligent features for easy adaptation to varying conditions, ensuring clean forage for maximum quality. Its size and flexibility make it ideal for medium-sized fields, and it requires minimal maintenance.

This rake features two to three rotors that place the swath beside the tractor and offers a working width ranging from 6.2 m to 7.4 m for single swaths. For the Twin-models a working with of 7.6 m to 8.2 m is possible while making two smaller swaths. It's designed with intelligent features for easy adaptation to varying conditions, ensuring clean forage for maximum quality. Its size and flexibility make it ideal for medium-sized fields, and it requires minimal maintenance.

Let technology assist you in achievinng clean forage!

The Swadro is designed to ensure minimal waste and clean feed. A test conducted by DLG (Deutsche Landwirtschafts-Gesellschaft) showed that Krones Lift Tines reduce soil and gravel contamination in the feed, regardless of working speed, and minimize losses by up to 2.1% compared to other systems. Furthermore, it is lifted in and out of operation in a way that prevents the tines from hitting the ground, thus avoiding feed contamination or damage to the ground surface.

Timing is crucial in a narrow harvesting window to save money!

Swadro TS is available in several different models, all designed to save time and increase efficiency. With two to three rotors, they cover a wide working width, and with the Twin models, you can adjust the working width telescopically to meet specific requirements. This allows you to change the width or swath position and work more efficiently while ensuring compatibility with the next machine in the process. Simple but large swaths are suitable for subsequent high-capacity forage harvesters and lighter crops, while double swathing (two smaller swaths) is suitable for subsequent machines with lower capacity or leafy crops.

Minimized downtime with field repairs!

If accidents occur, quick recovery is crucial as the value of forage diminishes with downtime. On the Swadro, a rotor arm can be swiftly replaced in the field without any oil spillage, saving time and money while also eliminating concerns about contaminated forage.

Reliable machines are the best friend of forage harvest!

Krone's Swadro models requires minimal maintenance due to its low-wear maintenance-free cam track and the hermetically sealed, lifetime lubricated main gear box. The combination reduces wear and upkeep costs, ensuring the rake is always field-ready. Only a daily visual inspection and lubrication of the power transmission shaft are needed, other maintenance is performed between harvests for a more efficient season. Farmers First Maintenance offers ready-made maintenance plans that contribute to reduced downtime, extended lifespan, and better resale value.

Clean forage and high work rates!

The robust Krone Lift Tines effortlessly lift heavy and wet crops off the ground. With a double bend design, they facilitate upward movement of forage along the tine. Compared to straight tines, they allow higher driving speeds without increasing losses or contamination. DLG (Deutsche Landwirtschafts-Gesellschaft), conducted a test showing that Krones Lift Tines reduce raw ash contamination in forage by less than 9% regardless of driving speed. They also minimize losses by up to 2.1% compared to other systems.

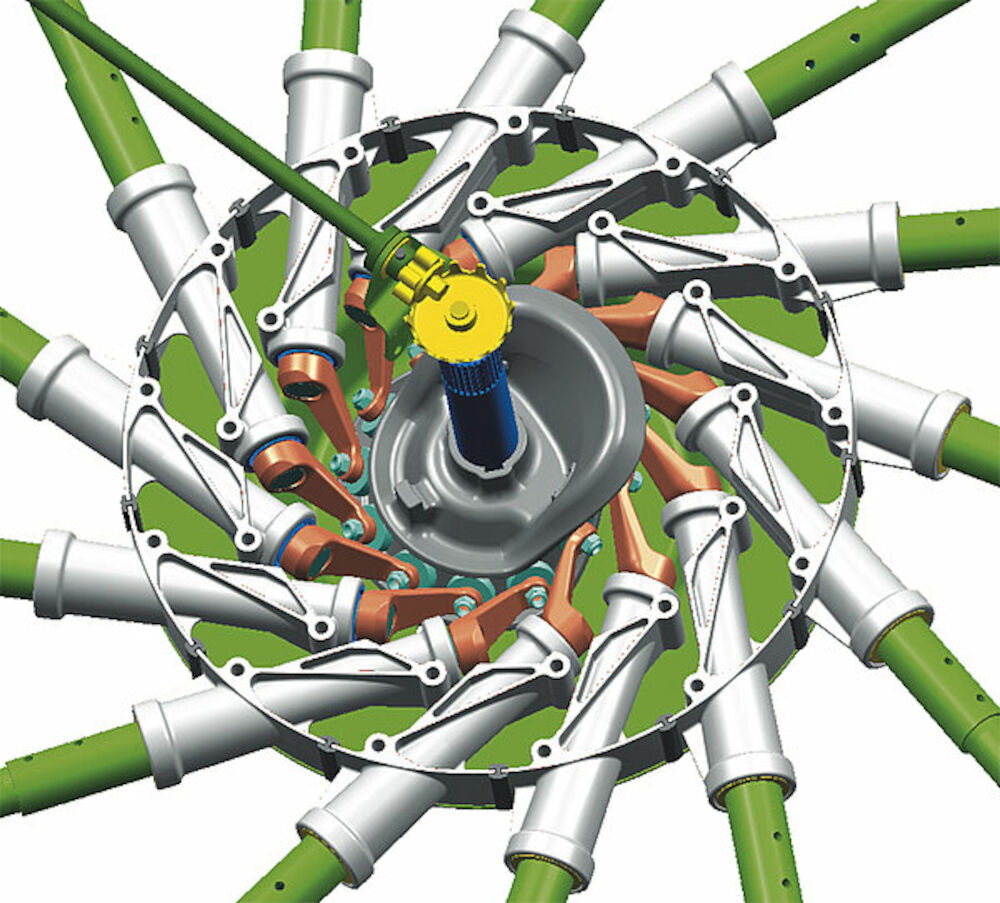

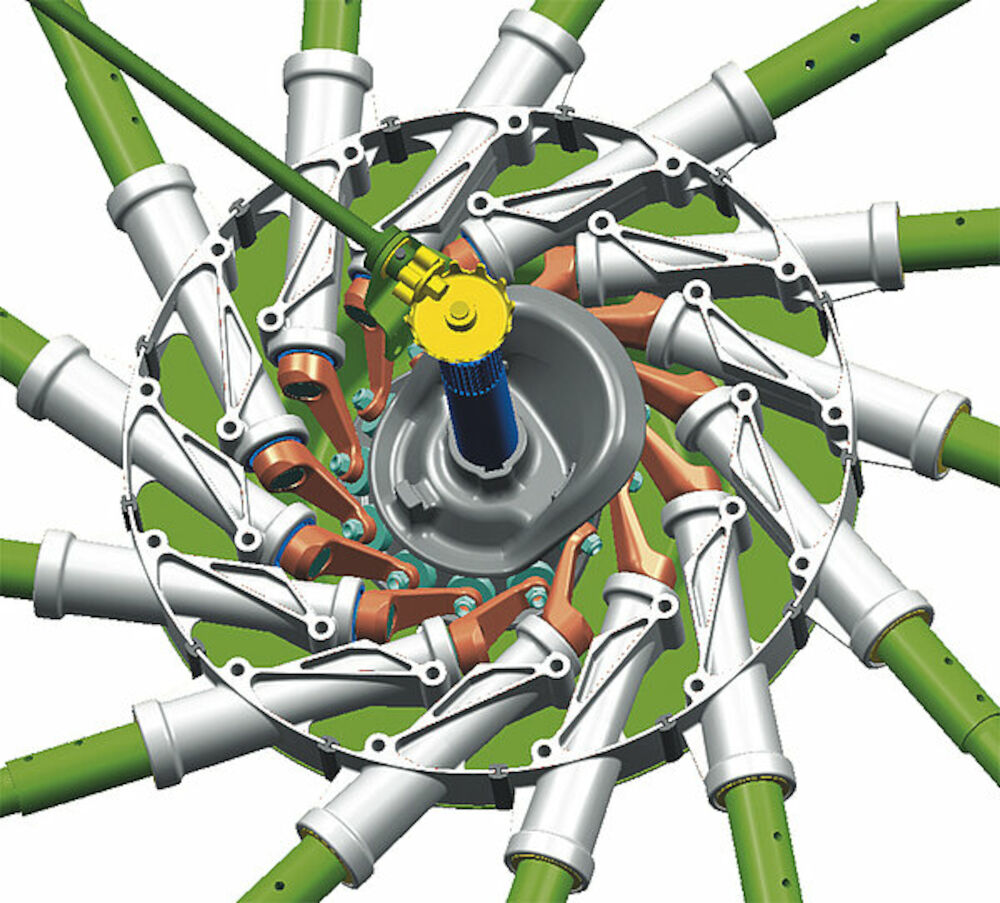

Change tine arm directly in the field

As most farmers have experienced, it is easy to bend a rotor arm when being in a hurry, and then, it's important to get back up and running quickly, as the value of the forage decreases with every hour of downtime. On the Swadro, a rotor arm can be quickly replaced in the field without any oil spillage because of the dry DuraMax cam track. It also has double ball bearings for stability, smooth control, and reduced wear. The durable tube is maintenance-free, securely connected to the control shaft for reliable and precise tine control.

Customized results for the following machine

With the Twin function, you can easily adjust the swathing telescopically to match the conditions and enhance efficiency:

- Single swath means that the forage is gathered into a single swath from both rotors with one pass in the field, which is suitable for high-yield crops or when using balers and small vehicles for forage handling.

- Large double swath can be formed by gathering two single swaths into a larger swath with passes back and forth in the field, which works perfectly in combination with subsequent machines that have high-capacity intake or lighter crops.

- Two separate swaths can be created by separating the rotors, which is ideal for subsequent machines with lower capacity or for crops with a lot of foliage.

Guaranteed function and reliability!

Maintenance-free and permanently lubricated and sealed gearbox make the Swadro a highly reliable partner in the harvest, regardless of the weather. This rotor rake is always ready for work and ensures reliable operation during the narrow harvesting window.

-No time is wasted on service stops.

-No lubricant out = no contaminants in!

-No time is wasted on service stops.

-No lubricant out = no contaminants in!

Protects the sward and produces clean forage!

Krones Jet Effect is inspired by an aircraft's takeoff and landing behavior in its rotor suspension design to ensure that there is always a maximum free space between the tine and the grass surface when the rotor is lowered and lifted out of operation. Without this margin, damage to the grass surface can occur, allowing weeds to grow, which in turn deteriorates the quality of the forage. However, with Swadro's design, these damages can be avoided, the tines last longer, and the result is clean forage.

Boxy and optimal swaths in all conditions

The Krone DuraMax cam track has a small diameter and steep track design made of special bainitic hardening that enables the tine arms to smoothly follow the curve and lift the tines out of work quickly and with ease. This innovative system ensures the formation of boxy and optimum swaths in all conditions, regardless of the terrain or crop density.

Can be used even with the smaller tractor and has low fuel consumption

The Swadro rake's rotor gearbox has a large gear ratio, ensuring low PTO speeds and minimal wear. This makes it compatible with small tractors, offering flexibility during harvest. The headstock has two positions for lower link attachment: a closer position for smaller tractors, reducing front axle load by up to 10%, and a longer position for bigger tractors with optimal maneuverability and large tires.

Achieve precise height control for optimal results

When it comes to height control, accuracy and reliability are paramount. That's why the Swadro rake is equipped with a manual crank that allows you to set the working height with millimeter precision, ensuring accurate ground contouring. With an easy-to-read scale, you can effortlessly adjust the rake to match the cutting height of your mower, eliminating guesswork minimize losses without contamination.

Tilt control for maximum efficiency

The lateral tilt control, set on the rear wheels, ensures minimal losses and the formation of boxy swaths. By tilting slightly towards the swath, the load on the tines is balanced, leaving no grass blade behind, even in heavy material. With an adjustable tilt using a pin/hole setting system.

Superior rakes in flat and undulating terrain

The rotor is suspended in a pull-type and cardanic configuration, ensuring 3D contouring, allowing for optimal contouring both in the direction of travel and across it. With this advanced system, the tines effectively pick up every straw without collecting a single grain of sand. The result is clean forage, minimal loss rates, and the ability to operate at high work speeds.

Ensuring reliable results and consistent ends

The hydraulic sequence control system prioritizes raising the leading rotor before the rear rotor reaches the headland position. This precise control is mechanically managed from a durable gate, allowing operators to customize the timing of arm movements to achieve consistent outcomes.

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.