First-class cutting quality and maximum crop flow with the self-propelled precision harvester BiG X 980!

With its impressive motor power of 979 hp, the KRONE BiG X 980 is a compact and powerful precision harvester that delivers superior cutting quality. It also offers outstanding user-friendliness and driver comfort in the harvesting of grass, corn, and whole grains.

With its impressive motor power of 979 hp, the KRONE BiG X 980 is a compact and powerful precision harvester that delivers superior cutting quality. It also offers outstanding user-friendliness and driver comfort in the harvesting of grass, corn, and whole grains.

First-class cutting quality

The self-propelled precision harvester BiG X from Krone is designed to deliver outstanding cutting quality. With six powerful intake rollers and a rapidly rotating drum, BiG X ensures a reliable grip on the crop, resulting in precise cutting lengths. The chopping drum can handle large amounts of material flow, and when it's time to change knives, adjustment is made easily using an eccentric.

Maximum crop flow

BiG X from Krone has a powerful engine designed to handle large amounts of crop smoothly. With intelligent design, BiG X ensures that the crop is efficiently fed into the chopping drum, where the chopped green mass is collected in pockets for smooth transport. Fuel consumption is adjusted according to the amount of green mass to be chopped, reducing the risk of blockages. Additionally, the VariStream technology provides an extra level of safety by using a spring-loaded bottom to handle even larger amounts of crop. When it's time to discharge the crop, the Stream Control function offers full control over the distance of ejection, which is especially useful when opening up a field.

High driver comfort, smart protection technology, and easy maintenance

When working long days, it helps to have assistance systems that relieve the driver and a design that makes the work easier. The BiG X cabin features a panoramic view to give the driver a clear overview of the working area. The control unit, consisting of a monitor and joystick, gives the user full control, and an automatic relief mode can be used for efficient work shifts. To minimize downtime and protect the machine, there is a stone detector on the intake rollers that identifies stones and stops the intake immediately. It also has a DEF fuel tank that lasts the whole day. To make maintenance easier, it has fewer moving parts to lubricate, and most service points are located on the left side for easy access.

Harvesting grass, corn, or whole grains

Whether you're harvesting grass, corn, or whole grains, BiG X offers the flexibility and versatility you need, and with just a few configurations, you can switch between applications. For grass harvesting, there's the impressive EasyFlow pickup, which, when paired with BiG X, delivers higher chopping quality and efficiency compared to traditional forage wagons. For corn harvesting, there are the options of EasyCollect and XCollect. The latter, XCollect, also breaks down the stalk, and if you want to maximize nutritional value even further, a kernel processor can be used. Finally, if you're facing whole grain harvesting, you can rely on the XDisc 620 header, which incorporates technology from Krone's EasyCut mower conditioner. This header becomes an excellent solution when the forage crop doesn't meet the original expectations, and growing grains need to be used as feed instead. With BiG X, you're ready for all your harvesting needs!

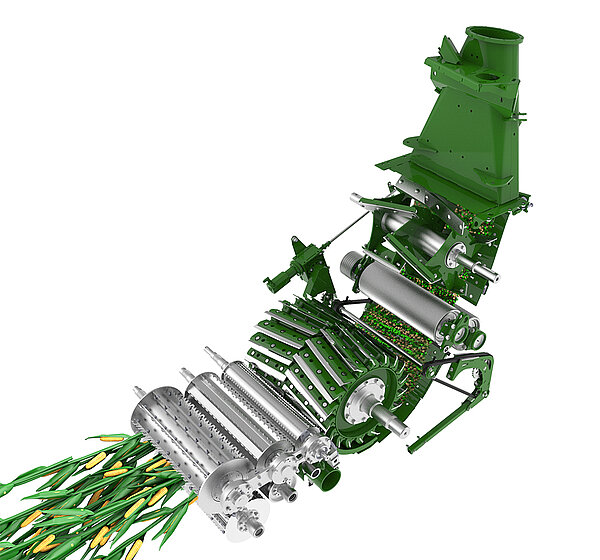

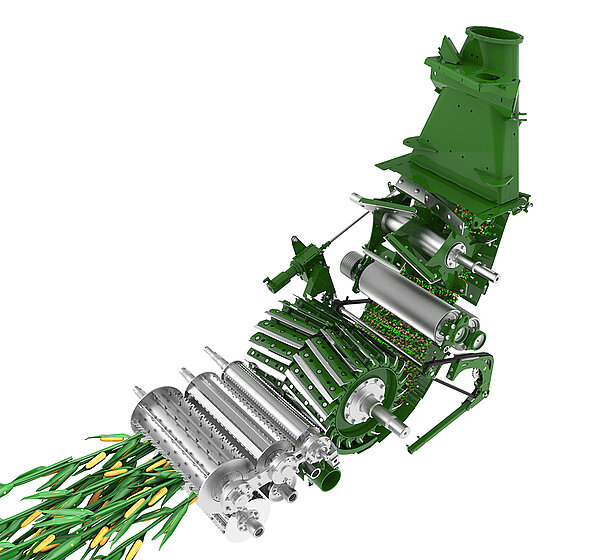

Crop flow through the machine

The BiG X from KRONE is the optimal self-propelled precision harvester for maximizing the quality of your crop. It offers outstanding cutting quality, high throughput, and superior user comfort. Here's what the crop flow looks like:

- Six intake rollers ensure high cutting quality.

- The universal chopping drum chops and transports the crop.

- VariStream technology can handle large amounts of crop in the machine.

- Easily adjust the distance to the throwing fan with StreamControl for precise accuracy.

Input is the key to achieving desired cutting quality

The advanced input technology on the BiG X is the key to easily achieving precise and efficient cutting length. The six hydraulic intake rollers securely hold the crop before it is fed into the drum. The speed can be adjusted continuously from the cabin, giving you full control over the process. Additionally, adjustable springs ensure that the pressure from the intake rollers is optimal, resulting in strong compression and outstanding cutting results. The generous opening between the six intake rollers and its robust drive enables superior flow capacity through the machine, even in demanding conditions.

The metal detector in the input system protects the machine

Advanced metal detection sensors in the front lower intake roller provide comprehensive protection against metal objects. These sensors carefully monitor the entire input width, reducing the risk of damage and downtime by detecting and warning of metal objects that may have been mixed into the crop. With this technology, your BiG X is both efficient and safe.

Easy maintenance for smooth operation

When maintenance is easy, there's a greater chance it will be performed, which is why the BiG X is designed with quick access to the chopping drum by disengaging the input system. If the chopping drum needs inspection in the field, the input system can be split in front of the chopping drum using the lifting hydraulics of the intake table and the detachable upper attachments. The lower attachments serve as hinges when the lifting hydraulics are gently raised with a button panel located on the left front fender.

Powerful and efficient chopping drum

When it comes to achieving high-quality forage, Krone's MaxFlow chopping drums guarantee perfect chopping. Choose from 20, 28, or 36 knives and customize the machine to your specific needs. The chopping drum is specially designed to produce high-quality silage while keeping fuel consumption low, thanks to its impressive flywheel mass and "pull-cut" technology. The knives are carefully placed in a chevron pattern at an 11° angle relative to the counter knife. This arrangement ensures a smooth flow process, minimizes noise levels, and maximizes efficiency. With the BiG X, you not only get outstanding cutting quality but also fuel-efficient performance for better machine economics.

Hassle-free knife changes

Getting the knives to sit correctly can be difficult and time-consuming, but getting it right is necessary to achieve high-quality cutting. With the BiG X, the knives are correctly set from the start, saving you time, and immediately delivering the best possible results. Using an eccentric, the knife can be easily mounted in the right place with just three screws, ensuring they are always correctly and securely fastened.

Efficient transport of the chopped crop in pockets

For smooth and worry-free crop handling, it is crucial that the crop is transported without hindrances or blockages. The BiG X is equipped with generous space beneath the knives and specially designed knife supports that ensure a free and even flow of the crop inside the machine. This helps increase flow rate and reduce noise levels, which is particularly noticeable when working with longer crops. The machine is also adapted to handle uneven flow with ease, accommodating clumps of a larger quantity of crop effortlessly.

Avoid blockages with the spring-loaded floor

The spring-loaded bottom called VariStream is positioned beneath the knife rotor. It dynamically adapts as the crops increase in volume, allowing the crop to be gathered before being fed out. This ensures that the high capacity is maintained without the risk of jamming in the knife drum, even if there's an extra influx of crop into the knife rotor.

Complete control of the crop stream

With StreamControl, you have full control over the process using a powerful crop accelerator that can be easily adjusted from the cabin. This allows you to fill the wagons with precision and minimal waste. Additionally, it relieves the engine when the distance to the wagon is shorter, providing more power for the actual chopping and increasing throughput.

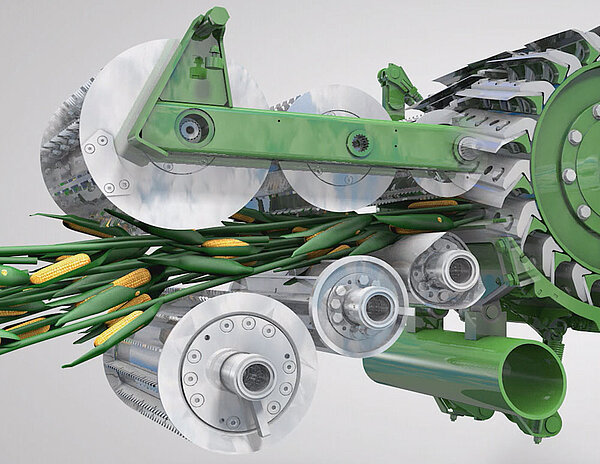

Safe and convenient suspension of the header

The BiG X is equipped with a robust frame for the header. The frame has guide rollers at the top and a support bar at the bottom, making it easy and convenient to attach and remove the header. With locking clamps, available as a hydraulic option, you gain precise control over the header. The suspension frame makes assembly even smoother, allowing you to start harvesting without hassle.

Optimal ground following with the pivoting lower attachment for the header

The header swings horizontally in the suspension frame secured by guide rollers. This attachment system is simple and straightforward, giving the header ample freedom of movement. The hydraulic cylinders on the sides allow the header to smoothly adapt to the terrain's contours. These hydraulic cylinders are pressure-free to enable seamless rotation.

Smooth attachment of the header

The BiG X features a practical coupling system that makes it quick and reliable to attach the header. It saves time and allows you to focus more on the work. You can choose between mechanical and hydraulic coupling, eliminating the need to leave the driver's cabin. The fast coupling, which can be hydraulic as an option, ensures a secure and easy connection of the drive system to the header, handling high loads effortlessly.

Secure locking

To lock the header, pins are used on the underside of the frame. As an option, you can easily manage these pins hydraulically from the driver's seat, making it convenient and safe to mount the header.

Efficient forage pickup

KRONE's EasyFlow 300 S and 380 S are pickup headers for grass harvesting without cam track. Compared to conventional pickups, EasyFlow has up to 58% fewer moving parts, making it much smoother, more durable, and cost-effective in terms of service and maintenance. EasyFlow works 30% faster for cleaner pickup and increased productivity. Learn more about EasyFlow here.

Efficient whole grain harvesting

The BiG X can be equipped with the advanced XDisc header, based on the proven technology from KRONE's EasyCut mower conditioners. This system allows the BiG X to cut and chop whole grains with a single machine. XDisc features SmartCut technology and a SafeCut function to protect the machine from foreign objects, delivering high performance and harvesting quality.

Efficient corn harvesting with EasyCollect

EasyCollect, the versatile corn header unit, offers outstanding results for corn harvesting. It feeds the corn stalks lengthwise, resulting in finely chopped high-quality corn harvests. EasyCollect's unique collection principle reduces labor costs and has proven to be reliable and efficient worldwide.

Increased versatility in corn harvesting with XCollect

KRONE has expanded the reliable EasyCollect series with the new XCollect headers. With XCollect headers, the cutting and feeding are separated into two distinct processes, meeting customer demands to handle different harvesting conditions around the world. This increased versatility allows you to effectively tackle a range of challenges in your corn harvest.

Additional features tailored for corn harvesting

During corn harvesting, there are more equipment options to choose from, such as Autoscan, which provides overload protection and adjusts the cutting length based on the corn's maturity, and the kernel processor OptiMaxx, which crushes the kernels. In addition to these, there's VariLOC to flexibly change the drum speed in minutes to match the crop you're working with. With the right settings, you can always achieve the cutting length that best suits your purpose.

Smooth transitions between crops

VariQuick is the system that allows you to quickly switch between corn, whole grains, and grass harvesting. By using a chain drive (electrically available as an option), you can easily move the kernel processor in or out of the crop flow. If the kernel processor is not in use, it can be easily lowered and removed from the machine by pulling it out to the side.

Easy transportation

Without any tools, transport wheels (optional) can be mounted on the kernel processor and pulled out to the side. This makes it easy to roll it into storage. With this convenient solution, transportation becomes simple and timesaving.

Powerful and fuel-efficient engine

With state-of-the-art technology from Liebherr, you get both power, smooth operation, low fuel consumption, high efficiency, and minimal maintenance in one. The engine power is easily controlled with a button press. Use the Eco-Power mode when full power is not needed to save fuel and quickly switch to the X-Power mode when more strength is required. The machine automatically and continuously adapts to current conditions. The engine speed control option also improves efficiency and fuel economy.

Easy service and efficient cooling

The engine is cross-mounted far back for optimal weight distribution and easy access. The cooling system, with rotating intake and exhaust systems above the discharge accelerator, keeps the temperature low even in dusty and dirty conditions. This means that your BiG X is always ready for top performance, regardless of the challenges.

Reliable and powerful drive system

The drive system in BiG X is designed to be reliable and simple. An extra-strong poly V-belt transfers power from the engine to the headers and other components. This provides long lifespan and reliable performance. The intake rollers and headers have separate hydraulic drive systems, allowing them to reverse if the knife drum suddenly stops. Furthermore, there is a separate and reliable drive line to the pumps that control the harvester's various functions. This smart design ensures that you can rely on your BiG X to perform powerfully and reliably, no matter the challenges you face in the field.

Powerful propulsion system for higher productivity

BiG X offers front-wheel drive as standard and all-wheel drive as an option. It is equipped with powerful Bosch-Rexroth wheel motors and has three driving modes and a speed range of 0–40 km/h. The hydrostatic wheel drive system increases productivity and minimizes maintenance needs, while allowing for a larger and more powerful chopping unit. The choice of 900 tires provides the best field performance. There are ut to seven different tire options to choose from.

Excellent equipment for long working days

To work long hours and at night, good visibility and excellent lighting are crucial. BiG X offers LED lights as an option for the best possible night vision. Its large fuel tanks, with a capacity of up to 1,450 liters of diesel with the additional tank option, reduce the need for frequent refills and increase productivity. Easy access to all components ensures smooth maintenance, keeping the machine in top condition. Additionally, an optional rear camera enhances visibility and safety. With BiG X, you can focus on maximizing your harvest without worrying about fuel and maintenance.

Comfortable cabin

The cabin of BiG X is designed to withstand long working days:

- Ample space and optimal climate control

- Large windows offer perfect visibility all around

- Maximum driver comfort during long working hours

- User-friendly operator terminal with color display and touchscreen

- Wider, quieter, and brighter cabin

- Sun visor

- Premium comfort options include a softer driver's seat, headrest, air conditioning, and a cool box for added convenience

Better visibility and increased comfort with LiftCab

With the height-adjustable LiftCab, the entire cabin can be raised up to 70 cm, providing the driver with better visibility over the field and the filling process. The elevated cabin also reduces noise levels and driver fatigue by increasing the distance between the cabin and the chopping units. With a simple push of a button, the cabin can be adjusted to the desired height, making the work both safer and more efficient.

User-friendly control systems

The control systems on BiG X are ergonomic and user-friendly, with over 20 programmed functions. The 8-inch color screen (12-inch as an option) provides access to important machine and harvesting data as well as camera images. You have full control over speed, direction, headers, and discharge flow to customize harvesting according to your needs and preferences.

Easier filling with EasyLoad (optional)

With the EasyLoad auto-filling system, combined with a camera-based 3D image analysis system, you can easily fill all types of transport wagons moving alongside BiG X. The system controls the "open/close outlet" and "rotate left/right" functions and allows you to choose among various filling strategies. You can easily monitor and control all functions from the harvester's driver cabin, making the filling process smooth and hassle-free.

Stone protection (optional)

The optional stone protection system, RockProtect, provides excellent protection against stone damage. It automatically stops the intake rollers within milliseconds after detecting a stone. The sensitivity of the RockProtect system is adjustable for extra protection. This helps avoid costly downtime and keeps the machine in its best condition.

-

Type of machine Selfpropelled forage harvester

-

Capacity fueltank 1100 l

-

Additional fuel tank 400 l

-

DEF tank capacity 150 l

-

Transport width 3,49 m

-

Transport height 3,98 m

-

Transport length 8,25 m

-

Weight, basic machine 17100 kg

-

57/43 %

-

Number of feeding rollers 6

-

Metal detector standard

-

82 cm

-

Infinitely variable from the cabin

-

80/66 cm

-

Arrangement of blades Chevron style, at 11° to counterblade

-

Number of knives standard 28

-

LOC range 4 - 22 mm

-

Cuts/ minute 17500

-

Stepless drum floor adjustment / spring-loaded drum floor Standard

-

Spec. cornconditioner Several configuration options

-

Angel of rotation 210 degree

-

Unloading height 6,00 m

-

34x23 cm

-

Automatic mirror function/parking position

-

Gearbox

-

Spout lined with wear plates throughout

-

Model Liebherr D 9512

-

Number of cylinders, engine capacity 12/24,24

-

Sustained engine power 979 hkr

-

Max power 720 kw

-

Max. continuous chopping output Eco Power 600 hkr

-

441 kw

-

Type of transmission infinitely variable hydrostatic drive with wheel motors for up to 40km/h (25 mph)

-

0-25 kmh

-

Max. roadspeed 0-40 kmh

-

Antislip control

-

4 Wheel drive Optional

-

Header drive Infinitely variable

-

Steering axle Rear axle

-

Hydraulic

-

Fronttyres 680/80 R38

-

900/60 R32, 710/70 R42 CHO, 710/75 R42, 800/70 R38 CHO, 800/70 R42 CHO, 900/60 R42 CHO

-

Rear tires 500/85 R30

-

710/60 R30, 620/70 R30 N, 620/75 R30, 620/70 R30 N, 710/60 R30

-

Automatic climate control

-

Air seat and buddy seat

-

Windscreen wipers on front and sides / Rear window wiper / 3 windscreen wipers Windscreen wipers on front and sides / rear window wiper

-

Type of header EasyFlow Pick-up, X Disc cutterbar and X Collect corn table

-

Tank capacity silage additives 275 l

General

Dimensions

Feeding

Chopperdrum

Spout

Engine

Wheels

Drivers Cabin mover

Attached implements

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.