Maximize your feed management with the EasyFlow Pickup!

With an impressive working width of 2.8 or 3.8 meters and high throughput capacity, it can handle various swath widths without compromising performance. It also features overload protection, increasing its durability and reducing maintenance costs.

With an impressive working width of 2.8 or 3.8 meters and high throughput capacity, it can handle various swath widths without compromising performance. It also features overload protection, increasing its durability and reducing maintenance costs.

Let technology enhance your top-notch feed management!

Boost your harvest with the EasyFlow pickup, delivering outstanding efficiency. With up to 30% faster working capacity than other options, you can save time and money while maintaining high harvest quality. EasyFlow is designed to handle various crops and terrains with high capacity and optimal ground tracking. Additionally, it automatically adapts to different swath sizes, making the harvesting process smoother and more efficient.

The best friend for forage harvesting is reliable machinery!

The powerful and dependable drive system of EasyFlow features a durable construction. With built-in overload protection in the drive system and fewer moving parts in the pickup, you can rest assured that it will endure and deliver consistent performance over the long haul. This not only saves you time and money but also provides you with more harvesting time when it's needed the most.

Adjust the machine according to the conditions

To achieve smooth and efficient operation, EasyFlow is optimally designed for ground contouring and string adaptation. With the ability to handle different string sizes and ensure high-quality forage regardless of the conditions, harvesting becomes both seamless and efficient, allowing you to save both time and resources.

Quick maneuvering and handling

Being able to quickly move between different fields and promptly address a blockage is essential for saving time. The adjustable lifting and lowering of support wheels make it easy to switch fields, and in case of an accident and a blockage occurs, accessing the feed channel can be done swiftly.

Streamline your harvest with a 30% faster pickup

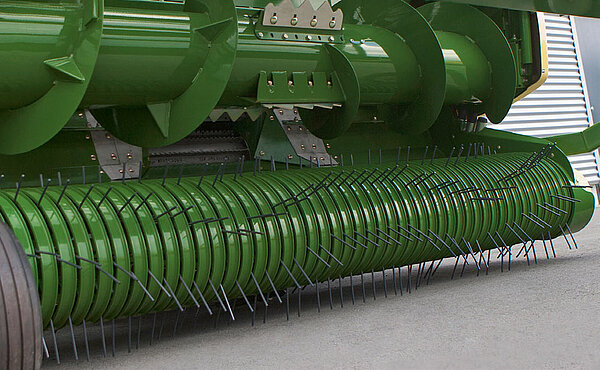

Smooth throughput is essential to avoid blockages during harvesting. With six axles and tine placement in a W pattern, EasyFlow can provide consistent crop collection while keeping the load and power requirements minimal. The result is not only efficient crop gathering but also maintained quality in challenging terrain. With these features, it can operate 30% faster than its competitors, allowing you to streamline your harvest and save both time and money.

High and reliable throughput

The equipment's ability to handle all types of crops and challenging terrain is a crucial factor for working efficiently. EasyFlow features a remarkable screw conveyor with a diameter of 600 mm, and the toothed intake plates made of Hardox wear-resistant steel can be adjusted in two levels of intensity. This allows it to manage even the most demanding crop conditions, whether they are dense or very long.

Powerful drivelines with overload protection

Smooth harvesting is essential for good profitability, and it requires reliable machinery. That's why EasyFlow features a powerful driveline capable of handling heavy loads. It also includes built-in automatic couplings with overload protection, extending the equipment's lifespan, reducing the need for repairs, and ensuring reliable performance in all conditions.

Increased durability with fewer moving parts

Performing maintenance during the harvest can be time-consuming and expensive, which is why Krone's EasyFlow is designed without a cam track and with 58% fewer moving parts than the conventional pickup. It is also constructed with durable materials to keep maintenance costs low and provide a long service life for a reliable and efficient harvest. The result is smoother operation, less wear and tear, and lower maintenance costs.

Quick handling of blockages

If a blockage occurs and the machine is reversed, the screw conveyor and string roller are automatically raised to provide easy access to the intake system. This facilitates the removal of foreign objects and ensures a smooth workflow.

Optimal ground following

EasyFlow dynamically adjusts to varying swath widths with continuous height adjustment and adjustable spring loading to achieve even pressure and crop flow into the pickup. Additionally, it is equipped with one or two (depending on the working width) rear ground following rollers that optimize ground following performance and prevent any feed from going to waste.

Quick field transitions

To quickly and easily move between different fields, we have equipped BiG X with height-adjustable support wheels. The support wheels can be easily folded up into transport mode with just the push of a button. This makes it smooth to travel between fields and get to work in no time.

Crop roller adapts to the swath

With EasyFlow, you get a pickup that automatically adapts to different swath sizes. It has continuous height adjustment and a spring-loaded suspension for the swath roller that compresses large, tall swaths for efficient collection. This ensures a constant speed and high-quality harvest regardless of swath size.

Safe and convenient suspension of the header

The BiG X is equipped with a robust frame for the header. The frame has guide rollers at the top and a support bar at the bottom, making it easy and convenient to attach and remove the header. With locking clamps, available as a hydraulic option, you gain precise control over the header. The suspension frame makes assembly even smoother, allowing you to start harvesting without hassle.

Optimal ground following with the pivoting lower attachment for the header

The header swings horizontally in the suspension frame secured by guide rollers. This attachment system is simple and straightforward, giving the header ample freedom of movement. The hydraulic cylinders on the sides allow the header to smoothly adapt to the terrain's contours. These hydraulic cylinders are pressure-free to enable seamless rotation.

Smooth attachment of the header

The BiG X features a practical coupling system that makes it quick and reliable to attach the header. It saves time and allows you to focus more on the work. You can choose between mechanical and hydraulic coupling, eliminating the need to leave the driver's cabin. The fast coupling, which can be hydraulic as an option, ensures a secure and easy connection of the drive system to the header, handling high loads effortlessly.

Secure locking

To lock the header, pins are used on the underside of the frame. As an option, you can easily manage these pins hydraulically from the driver's seat, making it convenient and safe to mount the header.

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.