Extend the forage season with efficient and reliable Comprima CV 150 XC!

This high-performance variable combination round baler provides maximum bale density and high capacity in all types of crops. It is designed for bale diameters ranging from 1 m to 1.50 m and features smart functions that contribute to its durability.

This high-performance variable combination round baler provides maximum bale density and high capacity in all types of crops. It is designed for bale diameters ranging from 1 m to 1.50 m and features smart functions that contribute to its durability.

A variable round baler that offers maximum flexibility!

The ability to adjust bale size and density is crucial for cost reduction. Larger straw bales reduce the number of bales to handle, transport, and store. Additionally, certain feeding methods may require smaller bales due to weight or feeding technique. With the flexibility to adjust bale size, you can optimize cost-effectiveness in the feeding process.

With the market's best baler grip, you avoid slipping in the bale chamber!

With KRONE's Comprima round baler, you not only get the market's best baler grip and safest bale rotation – the bale chamber mat also comes with a 3-year or 30,000 bale guarantee! The bale chamber mat's two NovoGrip belts are made of durable reinforced rubber to provide ultimate strength and long lifespan so that the baler can produce well-shaped high-density bales in all different crops. See a strength test where the bale chamber mat is tested against the force between a large tracked tractor and a brake wagon by clicking on the image!

Let technology help you achieve top-quality feed management!

During the forage harvest, a period of high stress and intense work, Comprima's technology can make life a little easier, and you can perform wrapping in the same pass, saving time. With a high-capacity pickup that works quickly and efficiently, you can quickly collect more feed and increase your productivity. If a stoppage occurs, the floor lowers, allowing you to quickly resume work. The fast open/close cycles ensure a production of maximum number of bales per hour, and with TIM technology, it can handle tasks autonomously.

Extend the harvest season and increase profitability

This baler can be used with all types of crops, whether it's silage, hay, or straw. You can be confident that you will get perfectly shaped bales throughout the season. Additionally, the baler comes with a standard warranty of 3 years or 30,000 bales for the NovoGrip slat elevator, reducing ownership costs and increasing reliability!

Reliable machines are the best friend of forage harvesters!

Reliable machines are invaluable for a smooth forage harvest. With Comprima's minimal maintenance and fewer loose parts, wear and tear are reduced, allowing you to focus more time on the harvest while saving money. Its lubrication system and easy access to centralized lubrication points make maintenance a simple task even during harvest. The Farmers First Maintenance App provides ready-made maintenance plans that contribute to reduced downtime, increased lifespan, and better resale value.

Maximum crop flow

With EasyFlow, you get maximum crop flow with reliable and efficient double 6 mm pins. The laterally pivoting pickup is known for effectively clearing fields in challenging conditions. With a working width of 2.15 meters, it allows for high-speed operation and thus achieves high hourly output. EasyFlow adapts smoothly to ground contours and is supported by a crop roller for efficient collection. Height adjustment is quick and easy for different crops and conditions, and the two flexible wheels navigate curves smoothly, ensuring nothing is missed.

Flexible to match the conditions

It's convenient to have a machine that can adapt to various conditions! You can easily adjust the number of active knives to 0, 8, 9, or a maximum of 17 knives as standard, with the shortest cutting length of 64 mm. Alternatively, you can choose from 0, 13, 13, or a maximum of 26 knives with a minimum cutting length of 42 mm as an option. There is also the possibility to adjust the size and density of the bales to suit your needs. For example, a less compact core is suitable for dry hay bales to allow better aeration of the warm grass, while a more compact core is ideal for straw, often transported over longer distances. With a highly flexible machine, you can meet various requirements and conditions.

Technology that prevents machine downtime

Accidents are hard to avoid, and when they happen, Krone balers have integrated damage protection. For example, each blade retracts from the crop if it is struck by an object, without affecting the other blades, and automatically returns to its working position once the object has passed. In the event of a blockage, the machine has a quick way to remove it by lowering the floor, allowing you to resume operation immediately and avoid lengthy and costly downtime.

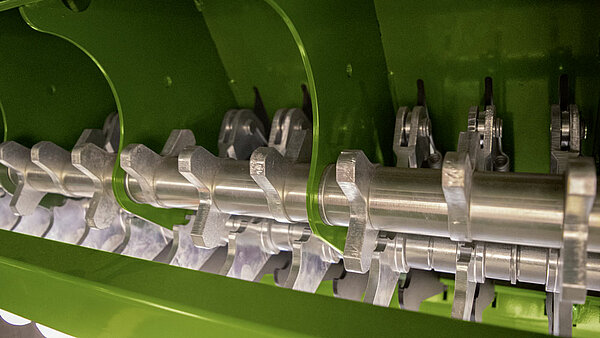

Safe and simple changes of knives

The knives have long, curved cutting edges that provide fuel-efficient cuts as the feed passes by. Their serrated edges cut all types of forage with precision and maintain sharpness for an extended period. All knives in the cassette are identical and are quickly interchangeable for easy maintenance. To insert or remove the knives, you simply lower the knife cassette. Unlocking the knives is accomplished by releasing all springs on the individual blade locking device with a single maneuver, allowing for convenient removal of the blades from above. If you only need half of the knives, you can easily set it up and then switch their positions after half of the day, continuing with new sharp knives without any interruptions for knife changes.

More efficient harvesting with flexible bale size

To achieve the desired bale size, bale density, and perfect bale shape is essential for obtaining an efficient forage harvest. From the heaviest silage, the two efficient NovoGrip bale chamber mats in the variable bale chamber press can provide exceptionally high density and form perfect bales. The tension on the NovoGrip mats is controlled hydraulically and through a system of tension arms. The bale pressure is gradually generated as the bale grows. The grip from the bale chamber mat's conveyors ensures the bale's rotation regardless of the circumstances. The bale diameter is variable and can be adjusted from the operator's terminal.

Optimal bale protection and easy operation

Get optimal protection for your bales and enjoy easy operation with Comprima's net wrapping system. It ensures high-quality edge protection, minimizes fragmentation, and guards against moisture, with the option of peripheral film wrap. Adjust wrapping conveniently from the cab while maintaining a clear view of the front-mounted wrapping unit. With quick net and film changes, you'll experience efficient operation, smooth handling, and exceptional bale protection every time! Click here to watch a video on how to change the net wrap.

Efficient and reliable bale wrapping

Comprima's wrapper ensures fast and reliable bale wrapping, even in challenging conditions and on sloping fields. Wrapping while moving to compress the next bale saves a lot of time and reduces field runs. With this wrapper, you get wide overlapping layers of plastic for added bale and knife protection. Additionally, there's a sealed storage space for 10 rolls of plastic film on the machine for easy field refills.

Improved performance under heavy load

A tandem axle is standard specification on the CF and CV combination baler and wrappers and an option on the F and V models. Tandem axles offer greater tongue loads, smoother rides and better road stability. As they offer a larger contact area, they also reduce rutting and protect the soil. There are three different tyre sizes available for this axle assembly.

More enjoyable and easier with ISOBUS

Krone's electronic system makes field work more enjoyable and easier. ISOBUS compatibility is a standard feature, offering the driver numerous possibilities. Choose from various terminals to find the one that best suits your needs.

-

PTO power requirement 100 hkr

-

Baler wrapper combination

-

Working width Pickup 2,15 m

-

Transport width 2,96 m

-

Transport height 3,08 m

-

Transport length 7,24 m

-

Hitching Rdawbar eye 40 mm

-

Auxillary valves on tractor 1xSA

-

Numbers of wheel axles 2

-

Trailerbrake Std, hydraulic or pneumatic

-

Baleturner Optional

-

Compartment wrapper plasticrollers Yes, 10 rolls

-

Net/ plastic film rollers compartment 1 spare roller

-

Croproller

-

Pickup specification Pivoting springloaded EasyFlow pickup. Camless, 6mm double tines in 5 helical rows spacing 55mm. Crop press roller and pivoting guide wheels.

-

Feeder rotor

-

Cutter

-

Cutting length std and optional 64 (42) mm

-

Cutter specifikation std 17 knives

-

Cutter specifikation optional 26 knives

-

Type of balechamber Variable

-

Balesize ( Width x Ø ) 120 x 100 - 150 cm

-

Net wrapping

-

Filmwrapping Optional

-

Automatic lubrication, grease

-

Greaseblocks

-

Automatic lubrication chainoil

-

Wrapper

-

Wheelsize (standard) 500/50-17 10 PR

-

Wheelsize optional 500/55-20 12 PR

-

Option

-

ISOBUS compatible

-

Traffic lights

-

Moisture measurement Option

-

Scale No

-

Hydraulic On-board hydraulics

General

Dimensions

Frame

Feeding

Balechamber

Lubrication

Wrapper

Wheels

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.