Maximum crop flow

With the Active pickup, you achieve maximum crop flow with five reliable and efficient rows of tines spaced at 55 mm intervals. The camless design is known for effectively clearing the field even under challenging conditions. With an impressive working width, it allows you to work at a high pace, resulting in a high hourly production rate. The Active pickup smoothly adapts to the field's contours with its pivoting support wheels and has a twine roller mounted on top that compresses large, tall swathes for efficient collection. The height is easily and quickly adjusted for different crops and conditions, and the two flexible wheels smoothly follow curves to ensure nothing is missed.

Consistent size and shape every time

For smoother handling and storage of bales, it is crucial that each bale is of the same size and shape. That's why all BiG Packs are equipped with technology that ensures a constant shape of the bales with each pressing. An electronic control for bale length is centrally mounted in the bottom of the bale chamber, and the operator can easily select the density from 0% to 100% via the control unit. Then, an intelligent pressure control system automatically adjusts the pressure in the bale chamber using two sensors that measure the force from the plunger. The bale chamber's design also ensures that each bale has smooth and neat edges.

Cutting system for short-chopped straw

VariCut is BiG Pack's cutting system with a variable knife control system distinguished by a maximum of 51 knives for producing high-quality short-chopped straw. The rotor and Pick-Up are belt-driven, offering maximum power and performance. In case of overload, the drive of the Pick-Up and rotor is automatically halted, and the knives are swung out of the material flow. Once the issue is resolved, work can be easily resumed hydraulically from the cabin by restarting the drive of the Pick-Up and rotor. Then, the knives are swung back into the material flow.

Integrated knife protection and easy replacement

The knife cassette in VariCut features a convenient service plate above the knives that can be easily folded up with a handle to remove crop residues and deposits. An integrated air pressure system with nozzles cleans the area around the knives and the individual knife protection system. The knife cassette is mounted on a retractable frame to keep the cassette together and maintain precision during operation, as well as to absorb any vibrations. Additionally, the frame with the knife cassette is easy to handle during maintenance; it can be effortlessly slid out to the side, removed, and transported with a pallet truck.

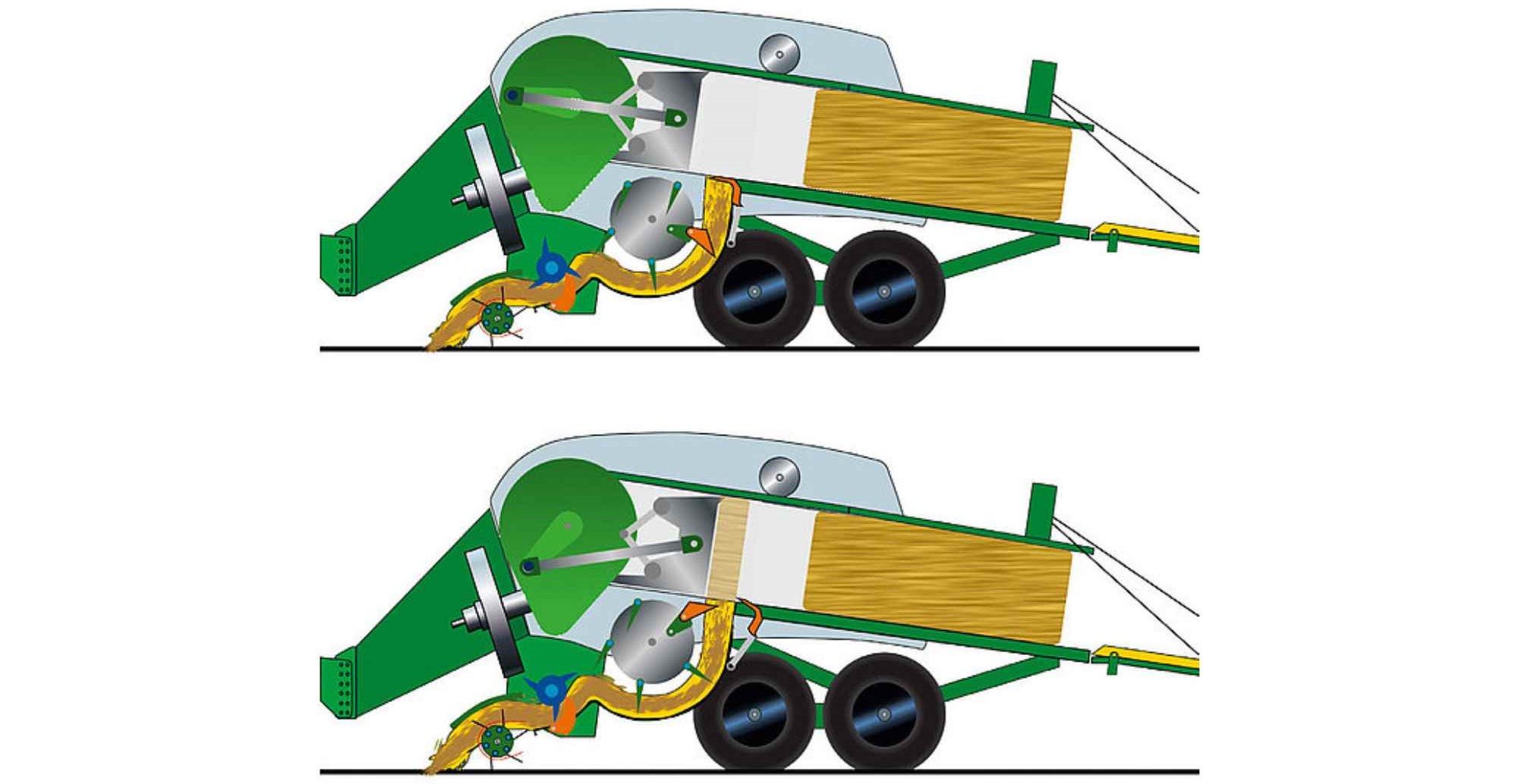

High bale density even at lower speeds

VFS (Variable Filling System) from KRONE helps create robust and heavy bales, even when working with small swaths and low working speeds. The material is fed into the feed channel of the pre-chamber where it is pre-compressed. Once the preset pressure is reached, it is lifted into the bale channel, forming a bale flake. In the chamber press, the bale fractions are compressed together by the piston., which strikes at 45 strokes per minute and gains extra power from the large flywheel. The PTO speed can be reduced to 800 revolutions per minute to make the piston strike 36 times per minute, creating robust bales even at lower speeds or with less material, while saving fuel. With an automatic overload clutch, the system ensures consistent maximum performance and evenly compressed bales.

Robust drive system

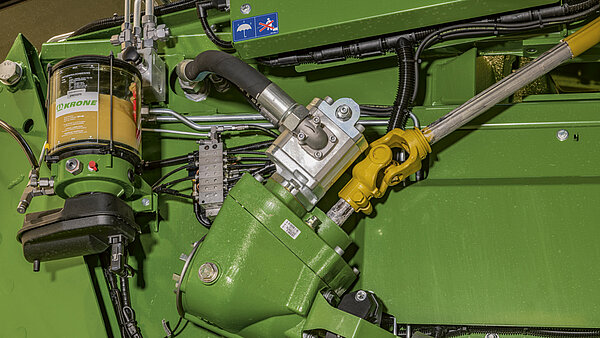

On Krone large balers, all power is transmitted through strong drive shafts, gearboxes, and overload protection, with no chains or shear bolts, which increases reliability. For the BiG Pack with VariCut, a separate 4-groove poly V-belt is used to drive the pickup and cutting unit. It automatically shuts off in case of blockages to prevent damage and only starts when the press is in operation. It is also protected by a slip clutch at startup and activates an automatic shutdown clutch in case of overload for extra safety.

Reliable knotting with the double knotter system

Producing high-density bales at high speeds with stable knots is a challenge. Therefore, Krone and Rasspe have developed a patented knotting system with compact V-twin knotters that handle twine with minimal pulling force. The result is perfect knots even in high-density materials and at high operating speeds, while leaving no twine remnants in the field. All BiG Pack Gen. 5 models are equipped with a cleaning system that uses an airstream from hydraulically driven fans for regular cleaning to ensure the knotters remain clean and can handle even the toughest and dustiest conditions.

Reliable machines are your best friend!

Reliable machines are invaluable for a smooth forage harvest. With minimal maintenance and less moving parts on the BiG Pack, wear and tear are reduced, allowing you to focus more time on the harvest while saving money. Its lubrication system make maintenance a simple task even during harvest. The Farmers First Maintenance App provides ready-made maintenance plans that contribute to reduced downtime, increased lifespan, and better resale value.

Efficient storage for long workdays

The updated storage space for bale twine has capacity for up to 30 pieces of bale twine, regardless of whether the twine rolls weigh 11 or 15 kg/piece. The sealed and dust-free twine boxes are integrated into the hydraulically lowering side panels and simply open upwards for easy refilling. The twine boxes have LED lighting as standard.

Better control of crop moisture (optional)

With the optional moisture meter, you can monitor crop moisture in real-time via the cab's monitor. The sensor provides a warning if the moisture level exceeds the preset thresholds, allowing you to optimize your harvest and ensure you create perfect bales every time.

Ensure the bales have the right weight (optional)

If you want to monitor whether the bale's weight meets your customers' needs, the integrated weighing system is the right option. The terminal not only displays the weight of each individual bale but also the total weight of the finished bales. With this system, you can ensure that you deliver exactly what your customers demand every time.

Optimize efficiency during harvest with BaleCollect! (optional)

A bale collector can greatly streamline the harvest when used in combination with the large baler. Krone's BaleCollect gathers up to three square bales that are 120 cm wide or five that are 80 cm wide. This makes it easier to save time, reduce costs, minimize soil compaction, and achieve high productivity during the harvest. Read more about the BaleCollect here.

Big boots and caster-steered tandem axle

All BiG Packs have the new BPW-axles and can be equipped with either 500/60 R22.5 or 620/50 R22.5 tyres. Despite different widths, both sizes maintain the machine width under 3 meters. The spring-suspended Boogie tandem axle ensures smooth and quiet operation at speeds up to 60 km/h, reducing strain on both the operator and the machine. The caster-steered rear wheels provide gentle handling of turns, and automatically lock in a straight-ahead position during reversing or high-speed travel.

Look good in the dark (optional)

The three optional LED work lights illuminate the area behind the baler and the front of the pickup. Easily connect the lights to the existing cable harness and control them from the terminal. With this option, you get the best possible visibility during night shifts.

Control Terminals

- High-resolution color displays with touch functionality.

- All KRONE BiG Pack large balers are ISOBUS compatible.

- If the KRONE BiG Pack is connected to an ISOBUS-compatible tractor, you can use the tractor terminal to control the baler.

Smooth Connection with Krone SmartConnect (optional)

Krone SmartConnect KSC is the core of KRONE's data management system. Whether you prefer Agrirouter, KRONE Smart Telematics, or just E-Solutions software licenses, Krone SmartConnect with its multi-network SIM card is the most convenient way to establish a connection. It automatically logs into the network that provides the best reception at the location and is standard equipment on BiG Pack.

Get a clear overview with KRONE Smart Telematics

Krone Smart Telematics provides an overview of machinery and data, streamlining the harvesting chain without unnecessary phone calls. Clear bale maps and detailed information accompany each bale, enabling comprehensive documentation. Data can be easily converted into PDF reports with just a few clicks.

Standing firm (optional)

To make it even easier to connect and disconnect the machine, this model can be equipped with a hydraulic support leg. This makes handling smooth and secure, and you can be confident that your equipment stands steady when not in use.

Smooth start and operation (optional)

The large flywheel, weighing approximately 610 kg, absorbs loads and keeps the machine running smoothly with less power consumption. The hydraulic motor accelerates the flywheel before engaging the tractor's PTO, and the intermediate gearbox reduces wear on the drive shaft while increasing the PTO speed for maximum flywheel performance. Some models may have hydraulic starting assistance as standard, while for other models, hydraulic start assist system ensuring smooth machine startup is optional.

Additional options

- Camera system for safe reversing

- Extra set of knives

- Hydraulic start assist

- Integrated moisture meter

- Integrated weighing system

- Various operator terminals

- Extra twine holder

- Silage additive system

- Agrirouter – database for data sharing

For over 100 years, KRONE has been a reliable manufacturer of modern forage machinery from Germany. Today, their product range includes premium machinery for forage harvesting, including balers, mowers, tedders, rakes, balers, and self-propelled forage harvesters.

KRONE is a family-owned company that delivers reliable, high-quality, and durable machinery with the goal of increasing customer productivity. They provide extensive training programs for their service personnel and maintain a large database to simplify troubleshooting and support.