Se våra färdiga erbjudande nedan. Har du andra önskemål? Boka ett möte med våra produktrådgivare så hjälper vi dig! Logga in för att se rätt pris.

Robusta VariPack V 190 XC Plus - en rundbalspress designad för maximal densitet och hög genomströmning!

Denna högpresterande balpress utmärker sig för maximal baldensitet och hög genomströmning av gröda. Den är designad för baldiameter från 0,80 m till 1,90 m och entreprenörer som behöver en robust maskin. Med sitt automatiska smörjsystem håller maskinen längre och lämnar mer tid till produktivt arbete i skörden.

Denna högpresterande balpress utmärker sig för maximal baldensitet och hög genomströmning av gröda. Den är designad för baldiameter från 0,80 m till 1,90 m och entreprenörer som behöver en robust maskin. Med sitt automatiska smörjsystem håller maskinen längre och lämnar mer tid till produktivt arbete i skörden.

Låt tekniken hjälpa dig att få en förstklassig foderhantering!

Under vallskörden, en tid av hög stress och intensivt arbete, kan VariPackens teknologi göra tillvaron lite enklare. Med en högkapacitetspickup som arbetar snabbt och effektivt kan du snabbt samla in mer foder och öka din produktivitet. Vid ett stopp i inmatningskanalen, kan knivbryggan sänkas för att släppa förbi blockeringen och arbetet kan snabbt återupptas. Cykeln för att öppna och stänga bakdörren är snabb för att säkerställa en produktion av maximalt antal balar i timmen och med TIM-teknik sköter den sig själv.

Flexibilitet så att du kan anpassa dig efter förutsättningarna

Med VariPacken får du den flexibilitet du behöver för att anpassa dig efter olika förutsättningar och behov. Du kan enkelt ställa in densiteten och storlekarna på balarna för att matcha dina krav, hö behöver exempelvis kanske produceras i mindre balar med lägre densitet i balkärnan för enkel hantering, medan halmbalarna kan pressas i större storlek och högre densitet för att minska transportkostnader. Det går också att välja antalet knivar som ska vara igång för längre eller kortare snitt, allt för att du ska få den flexibilitet som behövs för en smidig skörd.

Vallskördens bästa vän är pålitliga maskiner!

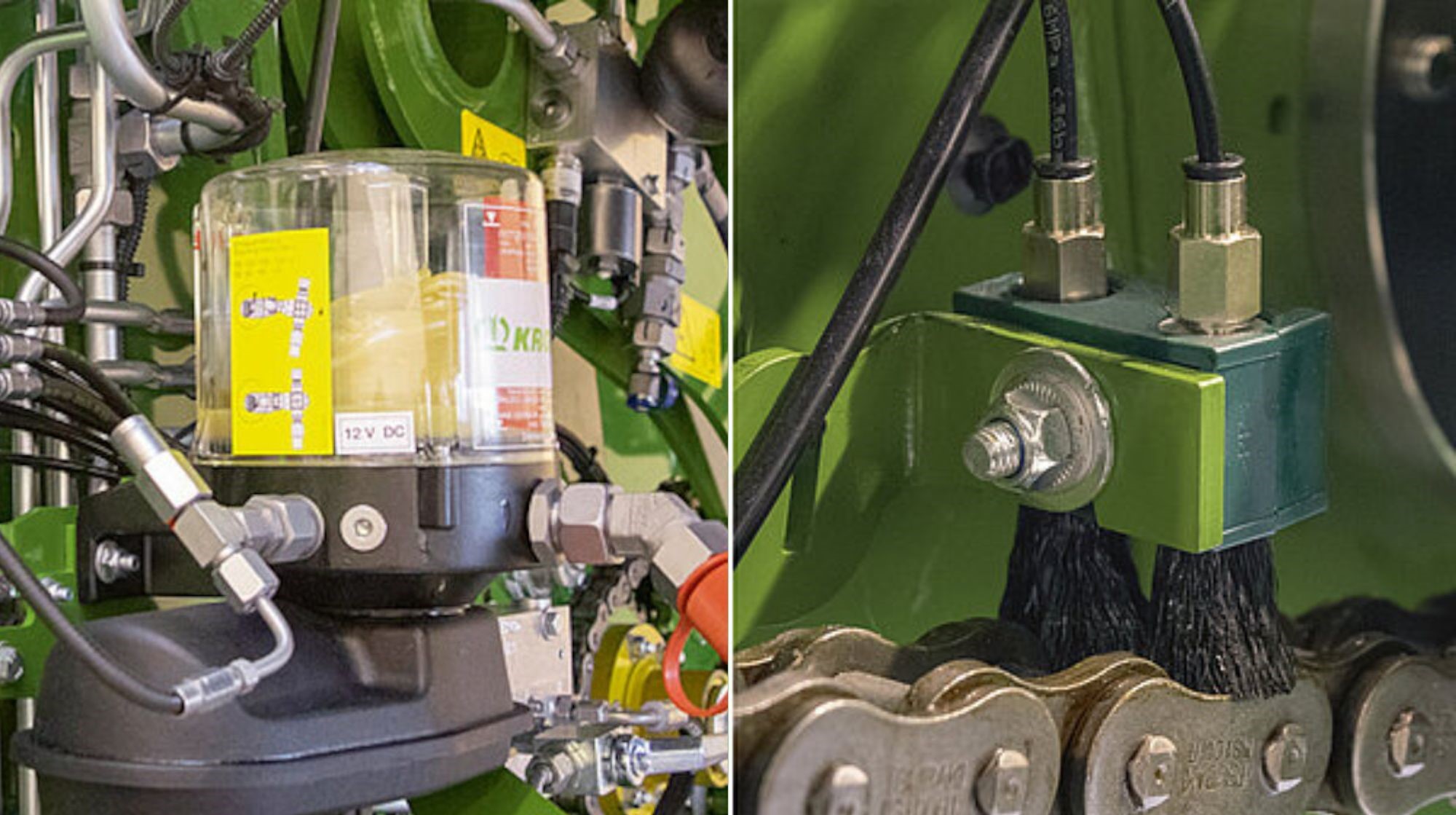

Pålitliga maskiner är ovärderliga för en smidig vallskörd. Med det minimala underhållet och färre antal lösa delar på VariPack Plus minskar slitaget, vilket innebär att du kan fokusera mer tid på själva skörden och samtidigt spara pengar. Dess automatiska system för både fettsmörjning av lager och oljesmörjning för kedjor gör underhållsarbetet till en enkel uppgift även under skörden. I Farmers First Underhållsapp finns färdiga underhållsplaner att använda som bidrar till minskad stilleståndstid, ökad livslängd och bättre begagnatvärde.

Robustare konstruktion för entreprenörerna!

VariPack V 190 XC Plus är en kraftfullare och mer effektiv version av VariPack V 190 XC, perfekt för entreprenörer. Den har högre baldensitet, fler knivalternativ och förbättrad foderinsamling, vilket gör den till det optimala valet för högpresterande vallskörd.

Flexibel för att matcha förutsättningarna

Det är smidigt att ha en maskin som kan anpassas till olika förutsättningar! Du kan enkelt ställa in antalet aktiva knivar mellan 0, 8, 9 eller max 17 knivar som standard och med kortast snittlängden 64 mm. Eller som tillval välja mellan 0, 13, 13 eller max 26 knivar med kortaste snittlängd 42 mm. Möjlighet finns även att ställa in balarnas storlek och densiteten för att de ska vara anpassade efter behoven. Exempelvis är en mindre kompakt kärna lämplig för torra höbalar så att det varma gräset kan luftas bättre, eller en mer kompakt för halmen som ofta ska transporteras längre. Med en maskin med hög flexibilitet kan man möta behoven och förutsättningarna.

Designad för att hålla länge

Under säsongen är det svårt att hitta tiden till de dagliga serviceåtgärderna för smörjning, men för att maskinen ska hålla länge är det viktigt att underhållet blir gjort. Därför har den här maskinen två automatiska smörjsystem; ett för central fettsmörjning som smörjer alla anslutna lager regelbundet och utan att föroreningar kan tränga in, samt ett för kedjesmörjning som smörjer maskinens drivkedjor med justerbar mängd olja. Det här lämnar mer tid till produktivt arbete i skörden samtidigt som den funktionella säkerheten och ekonomiska effektiviteten förbättras.

Effektiv, snabb och pålitlig balkammare

Balkammaren består av tre ändlösa remmar tillverkade av gummi med två inbäddade tyglager och är tillverkade med specialiserad ytdesign för att förhindra slirning och garantera pålitlig drift. Remmarna hålls konstant rena av två rullar för att säkerställa att de kan bibehålla sin effektivitet. Tillsammans skapar detta förutsättningar för högsta driftsäkerhet och effektivitet. Med det greppvänliga materialet på remmarnas yta görs VariPack Plus till en specialist på balpressning av torra material som halm och hö.

Snabba stopp för ökad produktion

Korta stopptider är avgörande för hög produktion vid rundbalspressning, att bakluckan öppnas och stängs snabbt är nyckeln till att producera fler balar i timmen. Krones Rundbalspressars bakluckor öppnas och stängs på mycket kort tid med hjälp av hydrauliska cylindrar med dämpning. Balarna läggs sedan säkert av på marken (även i sluttningar). Bakluckan kan dessutom styras automatiskt med TIM för ännu snabbare urlastningscykler.

Kraftfullare och Effektivare med Plus versionen

VariPack V XC Plus modellerna är kraftfullare version än VariPack V XC. Den har utrustats med tre remmar i presskammaren (två smalare och en bredare i mitten) jämfört med de fyra på den vanliga modellen, vilket möjliggör högre baltäthet. Dessutom kan du välja mellan 17 eller 26 knivar för snittverket, medan standard versionen av VariPacken har 17 knivar som standard. Plus-versionen har en extra pinnrad i pickupen för effektivare foderinsamling och större standardhjul för ökad stabilitet. Den har också automatisk fettsmörjning utöver den vanliga automatiska kedjesmörjningen, vilket förenklar underhållet.

Maximalt flöde av grödan

Med EasyFlow pickup får du maximalt flöde av grödan med pålitliga och effektiva dubbla 6 mm pinnar. Den pivoterande pickupen är känd för att effektivt rensa fältet även under svåra förhållanden och med en arbetsbredd på 2,15 meter gör den att du kan arbeta i högt tempo och därmed få en hög timproduktion. EasyFlow anpassar sig smidigt till markkonturen med svängande stödhjul och har en strängrulle monterad i överkant som trycker ihop stora höga strängar för effektiv insamling. Höjden justeras enkelt och snabbt för olika grödor och förhållanden och de två flexibla hjulen följer kurvor smidigt så att inget missas.

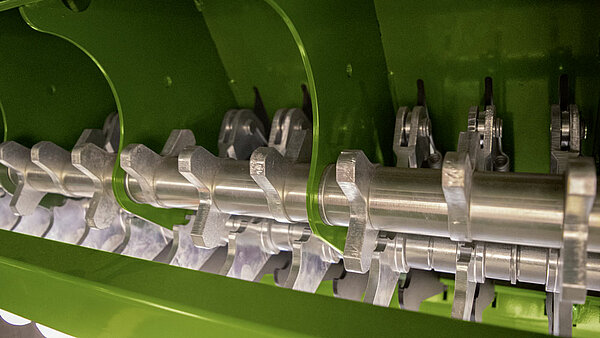

Snabba och enkla knivbyten

Knivarna har långa, böjda skärkanter som ger bränsleeffektiva snitt när fodret dras förbi dem. Deras vågiga kanter skär alla typer av foder med precision och behåller skärpan längre. Alla knivar i kassetten är identiska och byts snabbt ut för att underhållet ska vara enkel. För att sätta i eller ta bort knivarna sänker man helt enkelt knivkassetten. För att låsa upp knivarna släpps alla fjädrar på den enskilda knivlåsanordningen med ett enda handgrepp, och man kan bekvämt ta bort knivarna ovanifrån. Om du bara behöver hälften av knivarna kan du enkelt ställa in det och sedan byta plats på dem efter halva dagen och fortsätta med nya, vassa knivar utan avbrott för knivbyten.

Teknik som skyddar maskinen från driftstopp

Olyckor är svåra att undvika, och när de händer har Krones balpressar ett integrerat skydd mot skador. Varje kniv drar sig exempelvis tillbaka från grödan, utan att påverka de andra knivarna, om den träffas av ett föremål och återgår sedan automatiskt till arbetsposition igen när föremålet har passerat. Skulle det bildas en blockering har maskinen ett snabbt sätt att avlägsna det genom att sänka knivbryggan så att det går att köra direkt igen och undvika långa kostsamma driftstopp.

Perfekt snittkvalitet för bättre resultat

För att uppnå hög kvalitet på dina rundbalat är en perfekt snittkvalitet avgörande. Krones rundbalpressar levererar enastående snittkvalitet med sin integrerade rotor och sitt snittverk. De dubbla rotorfingrarna förhindrar att material glider förbi knivarna, vilket leder till tyngre balar och högre densitet. Dessutom säkerställer helix-designen på rotorn en smidig och tyst drift utan toppbelastning i skärsystemet. Tillsammans med de chevron-formade pinnarna på pickupen garanterar detta ett jämn flöde av material till snittverket, vilket ger optimal genomströmning och enhetliga rundbalar.

Smidigt nätsystem med smart förvaring

Nätsystemet är enkelt, pålitligt och bekvämt att använda för att spara tid under skörden. För de längre arbetsdagarna finns förvaring av en extra nätrulle på maskinen och det är enkelt att se hur mycket nät som finns kvar från traktorhytten. Vid byte av den tunga nätrullen kan den rörliga förvaringsvaggan på vänster sida av maskinen vikas ut så att nätrullen med enkel kraft kan skjutas över till avsedd plats, utan att behöva lyftas.

Minska tiden för underhåll och öka produktiviteten

När det är enkelt att underhålla kan man lägga mer tid på arbetet, vilket ökar produktiviteten. Därför är många av maskinens lager och vridpunkter anslutna till ett automatiskt fettsmörjningssystem. De tre kedjorna har automatiska kedjespännare som smörjs med individuell mängd olja via det automatiska smörjsystemets som har en behållare för sju liter kedjeolja. Detta minskar slitage avsevärt och leder till betydande tids- och kostnadsbesparingar samtidigt som det förbättrar den funktionella säkerheten och ekonomiska effektiviteten.

Roligare och enklare med koppling till ISOBUS och TIM

Krones elektroniksystem gör arbetet på fältet roligare och enklare. ISOBUS-kompatibilitet och TIM-förberedd är standardfunktioner och ger föraren många möjligheter. Välj bland olika terminaler och hitta den som bäst passar dina behov. TIM (Tractor Implement Management) möjliggör datadelning mellan maskinens ISOBUS-jobbdator och traktorn, vilket gör att redskapet kan styra traktorn och avlasta föraren. Detta innebär ökad effektivitet, mindre ansträngning för föraren, lägre bränsleförbrukning och jämnare balar så att arbetsdagen blir mer produktiv och roligare.

-

Maskintyp Rundbalspress

-

PTO effektbehov traktor 100 hkr

-

Kombimaskin med plastare

-

Arbetsbredd Pick-Up 2,15 m

-

Transportbredd 2,75 m

-

Transporthöjd 3,05 m

-

Transport längd 4,90 m

-

Tillkopplingsdrag Hitchögla 40 mm

-

Krav yttre ventiler traktor LS eller OC, fri retur

-

Antal hjulaxlar 1

-

Släpvagnsbroms Standard, hydraulisk eller pneumatisk

-

Pick-up typ EasyFlow

-

Strängrulle

-

Pickup specifikation EasyFlow pickup, rörlig och avfjädrad upphängning 6 mm dubbla pickup fingrar i 5 rader utan kamstyrning. Avstånd mellan fingrarna 55 mm, fingrarna sitter i ett W mönster. Strängpressrulle och svängbara stödhjul.

-

Inmatningsrotor

-

Snittrotor specifikation XCut rotor Hardox, 530 mm med dubbla inmatningsfingrar i vågmönster

-

Snittverk

-

Snittlängd std (tillval) 64 (42) mm

-

Snittverkets specifikation standard 17 knivar

-

Snittverkets specifikation tillval 26 knivar

-

Balkammar typ Variabel med remmar

-

Balstorlek ( Bredd x Ø ) 120 x 80 - 190 cm

-

Nätlindning

-

Mantelplastning

-

Centralsmörjning fett

-

Samlade smörjpunkter

-

Centralsmörjning olja, kedjor

-

Inplastare

-

Hjulstorlek (standard) 500/55-20 12 PR

-

Hjulstorlek, alternativ 500/60 R 22.5, 600/50 R 22.5

-

Terminal Tillval

-

ISOBUS kompatibel

-

Färdljus

-

Hydraulsystem LS eller OC+ fri retur